Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

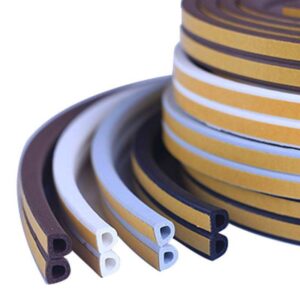

EPDM rubber seal strips

EPDM Rubber Seal Customizable Extrusion Processing Service High Quality Black Sealing Strip -50 to 150

- Wide temperature resistance (-40°C to 150°C) for extreme climates

- Superior weather, UV & ozone resistance for long outdoor service life

- Excellent sealing performance with strong compression recovery

- Good resistance to weak acids, alkalis and common chemicals

- Cost-effective, durable and customizable for doors, windows & industrial use

EPDM rubber seal strip is a versatile, durable sealing component made from ethylene propylene diene monomer (EPDM) synthetic rubber, engineered to deliver reliable gap-sealing performance across residential, commercial, and industrial applications. As a cost-effective and long-lasting sealing solution, it is widely favored for doors, windows, HVAC systems, automotive parts, and heavy-duty machinery, addressing core user needs of airtightness, waterproofing, and noise reduction.

One of the key advantages of weatherproof EPDM seal strips is their exceptional environmental resistance. Unlike conventional rubber strips, EPDM variants boast superior tolerance to UV radiation, ozone, and harsh weather conditions, ensuring a service life of 8-10 years outdoors without cracking, hardening, or performance degradation. This makes them ideal for outdoor applications like building facades, automotive door seals, and outdoor machinery enclosures.

With a wide temperature range of -40°C to 150°C, EPDM rubber sealing strips perform reliably in extreme cold and high-heat environments, from frigid industrial warehouses to high-temperature HVAC ductwork. They also exhibit strong resistance to weak acids, alkalis, and common industrial chemicals, maintaining sealing integrity in corrosive settings without compromising elasticity.

For residential and commercial use, EPDM seal strips for doors and windows effectively block air leaks, water seepage, dust, and noise, enhancing energy efficiency by reducing heating and cooling losses. Their excellent compression recovery ensures a tight seal even after repeated opening and closing, while customizable sizes and shapes adapt to diverse gap dimensions, from narrow window frames to large industrial door gaps.

As a cost-effective alternative to silicone seal strips,industrial EPDM rubber seals offer balanced performance and affordability, making them a top choice for bulk orders in construction, automotive, and manufacturing industries. Compliant with global quality standards, they meet safety and durability requirements for both indoor and outdoor applications, solidifying their position as a trusted sealing solution for businesses and homeowners alike.

EPDM (Ethylene-Propylene-Diene Monomer) rubber seal strip is a high-performance sealing solution widely used in construction, automotive, and industrial fields. Its specifications are tailored to ensure excellent durability, weather resistance, and sealing performance, meeting global industry standards and customization needs.

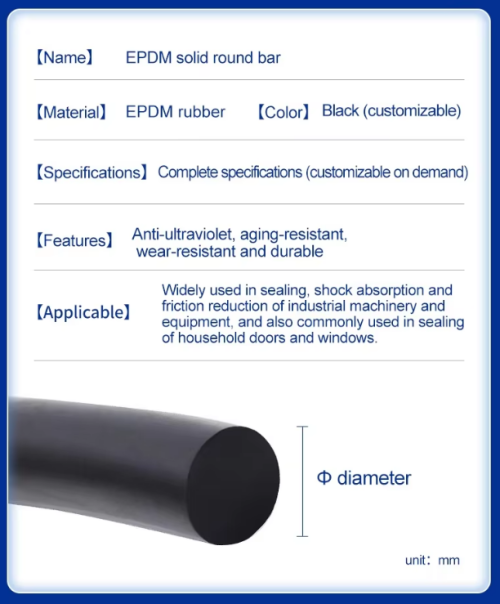

Core Material & Physical Specifications

Made of premium EPDM rubber, the seal strip features adjustable hardness from 30 to 90 Shore A, with 70±5 Shore A as the standard for universal applications . The specific gravity ranges from 1.15 to 1.35 g/cm³, and tensile strength reaches 10-14 MPa, ensuring strong structural stability . Elongation at break is up to 245% (ASTM D412-C), and compression set is as low as 9% (24h, 150°C, ISO 815-B), maintaining elasticity after long-term compression .

Thermal & Environmental Resistance

It boasts an extreme temperature tolerance of -60°C to 150°C, adapting to harsh climates from frigid winters to scorching summers . With outstanding ozone, UV, and water resistance, it resists aging, cracking, and degradation even in outdoor exposure for years . It also withstands polar fluids and mild chemicals, with minimal volume change (≤+2%) after immersion tests .

Dimensional & Customization Specifications

Standard widths range from 4mm to 1m, thicknesses from 1mm to 50mm, with RMA E2 cross-sectional tolerance . Custom profiles (D-shape, T-shape, bulb trim) are available via 2D/3D drawings, with self-adhesive or steel-embedded options for easy installation . Color is black as standard, with custom colors offered. Packaging is 50-300 meters per roll, supporting MOQ 100 meters .

Certifications & Applications

Compliant with ISO 9001, TS 16949, RoHS, and REACH, it’s ideal for windows, doors, automobiles, HVAC, and marine equipment . It provides dustproof, waterproof, sound-insulating, and shock-absorbing effects, serving as a reliable sealing choice for global clients .

What temperature range can EPDM rubber seal strips withstand?

They perform stably from -40°C to 150°C, adapting to extreme cold and high-heat environments for indoor and outdoor use.

How long do EPDM seal strips last outdoors?

With excellent UV and ozone resistance, their outdoor service life can reach 8-10 years without degradation.

Are EPDM rubber seals resistant to chemicals?

Yes, they resist weak acids, alkalis, and common industrial chemicals, maintaining sealing performance in corrosive settings.

What applications are EPDM seal strips suitable for?

They are widely used for doors, windows, HVAC systems, automotive parts, and industrial machinery.

Can EPDM rubber seal strips be customized?

Absolutely, they come in customizable sizes and shapes to fit diverse gap dimensions and application needs.

EPDM rubber seal strips are high-performance sealing solutions trusted across construction, automotive, HVAC, and industrial manufacturing industries—valued for their superior weather resistance, chemical stability, and long-lasting durability.

In construction, EPDM seals are installed in doors, windows, curtain walls, and expansion joints, effectively blocking wind, rain, dust, and noise while reducing air leakage to improve building thermal insulation and energy efficiency. For the automotive sector, these strips are critical for car doors, windows, trunks, and sunroofs, ensuring cabin airtightness, soundproofing, and protection against UV rays and extreme temperature fluctuations.

In HVAC systems and household appliances (e.g., refrigerators, freezers), EPDM seals maintain internal temperature stability and prevent air/water leakage to boost energy efficiency. Additionally, in industrial settings, they seal heavy machinery, pipelines, and equipment, withstanding exposure to oils, acids, and harsh environments—making them a reliable choice for both indoor and outdoor applications.