Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

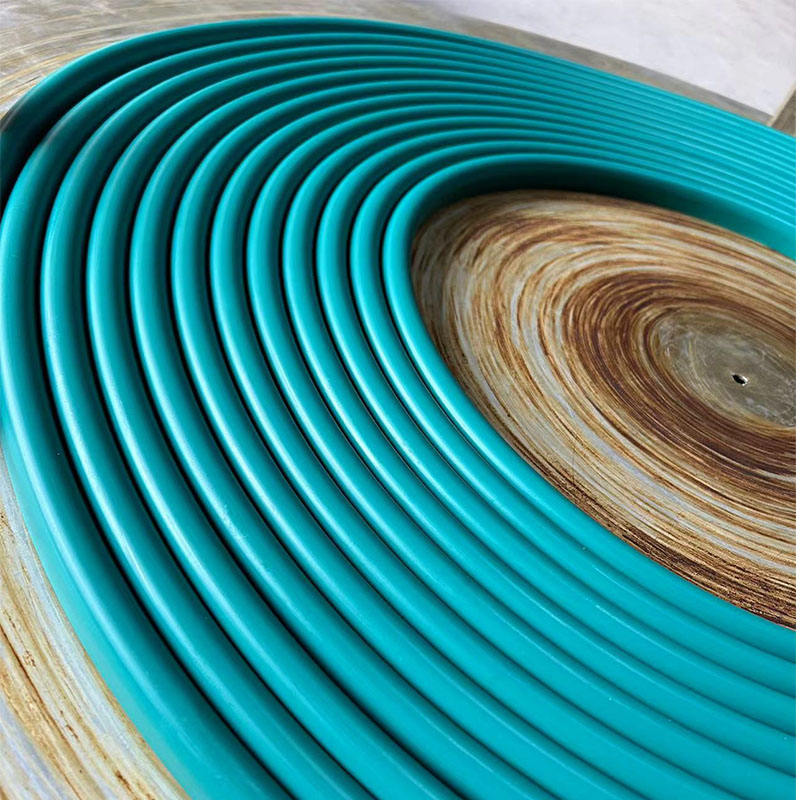

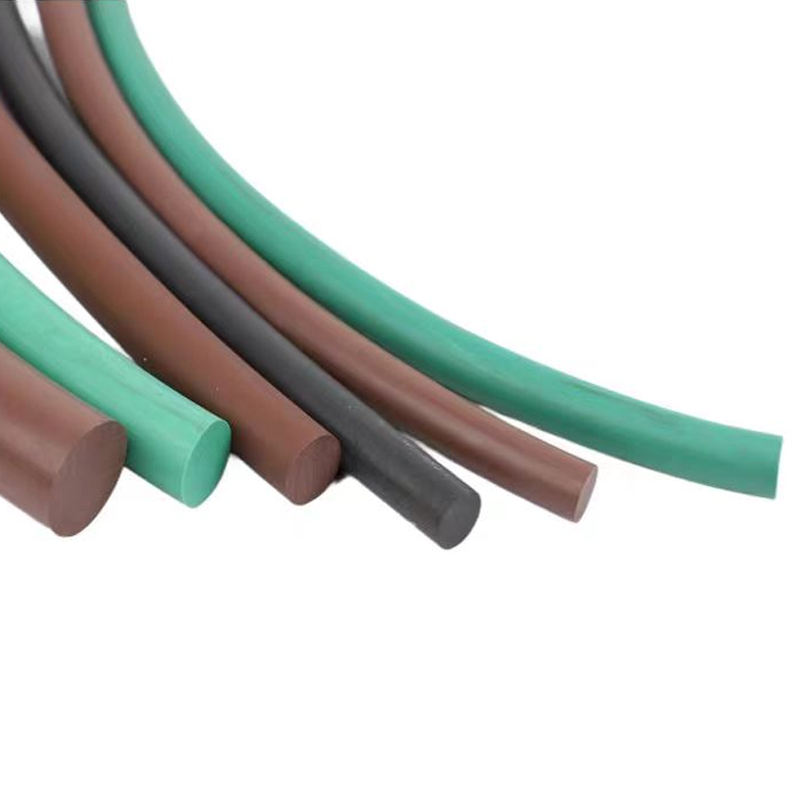

FKM Rubber Seal Strip

Industrial FKM Rubber Sheeting for Custom Gasket Fabrication & Tank Lining

- Temp range -20℃~260℃, oil-resistant with excellent sealing performance

- Strongly resists acids & solvents, reliable chemical corrosion protection

- UV & aging-resistant, features an extended long service lifespan

- Low compression set rate, ensures high structural stability

- Adapts to extreme working conditions, wide industrial applications

- Fully customizable with flexible specifications for diverse needs

FKM rubber (fluoroelastomer) is one of the most reliable and highest-performing elastomeric materials in the industrial sealing field. Whether you are looking for FKM rubber gaskets, FKM rubber sheeting, or custom seals, understanding the unique properties of this material is crucial for selecting the correct solution.

Key Chemical Properties

The molecular backbone of FKM rubber contains fluorine-carbon bonds, among the strongest chemical bonds in nature. This molecular structure gives FKM:

Extremely high chemical inertness

Outstanding thermal stability

Exceptional resistance to degradation

Types of FKM Rubber Seals

1. FKM Rubber Gaskets

FKM rubber gaskets are widely used in applications requiring reliable sealing and chemical resistance:

Flange connections in chemical processing equipment

Piping systems in oil and gas

Pharmaceutical processing equipment

Fuel handling systems

These gaskets provide static sealing, preventing leakage of liquids and gases under extreme conditions.

2. FKM Rubber Sheeting

FKM rubber sheeting is a versatile material supplied in rolls or sheets, used for fabricating custom seals, liners, and washers on-site. Its applications include:

Cutting and stamping custom gaskets

Lining chemical tanks and vessels

Creating seals for complex flange faces

Emergency repair patches for critical equipment

3. Molded & Extruded FKM Seals

This category includes O-rings, custom-molded seals, and extruded profiles. They are precision-engineered for dynamic and static applications in:

Automotive fuel systems and valve stem seals

Aerospace hydraulic systems

Semiconductor manufacturing equipment

The superiority of FKM seals stems from their unique combination of properties:

Extreme Temperature Resistance: FKM maintains elasticity and sealing force within a typical range of -20°C to +200°C (-4°F to +392°F), with special grades extending up to 300°C (572°F) for short periods.

Exceptional Chemical and Fluid Resistance: It demonstrates excellent resistance to oils, fuels, hydraulic fluids, acids, aliphatic and aromatic hydrocarbons, and many halogenated solvents. This is its most significant advantage over NBR, EPDM, and Silicone rubbers.

Excellent Weathering and Aging Resistance: FKM performs superbly against ozone, UV radiation, and atmospheric oxidation, ensuring long-term reliability in outdoor applications.

Good Mechanical Properties: It offers satisfactory tensile strength, elongation, and compression set resistance for demanding sealing applications.

Low Gas Permeability: Compared to many other elastomers, FKM has very low permeability to gases, making it ideal for vacuum and high-pressure gas systems.

Comparison with Other Common Rubber Materials

| Property | FKM (Viton®) | NBR (Nitrile) | EPDM | Silicone |

|---|---|---|---|---|

| Max. Temp. Resistance | Excellent (up to 200°C+) | Good (120°C) | Good (150°C) | Excellent (230°C) |

| Oil/Fuel Resistance | Excellent | Excellent | Poor | Poor |

| Chemical Resistance | Excellent | Good | Good (to polar solvents) | Fair |

| Weather/Ozone Resistance | Excellent | Fair | Excellent | Excellent |

| Cost | High | Low | Low | Medium |

What is the difference between FKM and Viton®?

How does FKM compare to Silicone and EPDM for chemical resistance?

What is the maximum continuous temperature for FKM seals?

Are FKM gaskets suitable for high-pressure applications?

How long is the shelf life and service life of FKM seals?

Automotive Industry: Fuel injector O-rings, valve stem seals, turbocharger hoses, ATF seals.

Aerospace: Hydraulic system seals, fuel system components, O-rings for engines.

Chemical Processing: Pump seals, valve liners, reactor gaskets, pipe flange seals handling corrosive media.

Oil & Gas: Downhole tool seals, blow-out preventer (BOP) elements, seals for drilling equipment.

Pharmaceutical & Food: Seals for sterilizable equipment (SIP/CIP) and processes involving aggressive cleaning agents.