Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

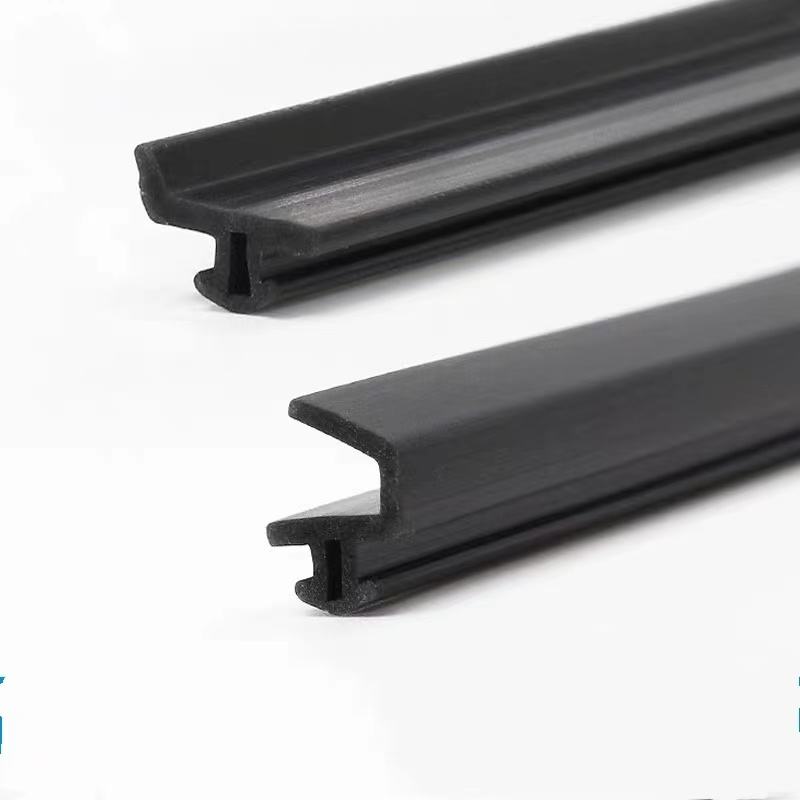

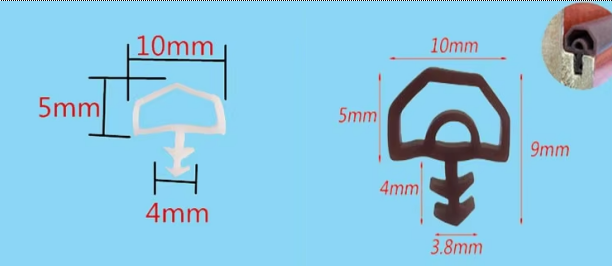

TPE/TPR Rubber Seal Strip

TPV/TPE Rubber Seal Strip for Window Aluminum Window Rubber Weather Seal Strip

- Hardness 0–90A, flexible & easy to mold

- Temp -40℃ to 120℃, good low-temp resistance

- FDA-compliant, safe for food & medical use

- Recyclable, eco-friendly & cost-effective

- Excellent adhesion, ideal for overmolding

- Wear-resistant, suits long-term industrial use

TPE Rubber, or Thermoplastic Elastomer, is a revolutionary material class that perfectly bridges the gap between traditional rubber and plastic. It combines the elasticity, flexibility, and soft-touch feel of vulcanized rubber with the easy processing, recyclability, and design versatility of thermoplastics. This unique hybrid nature makes TPE a top-choice material for engineers and buyers seeking innovative, cost-effective, and eco-friendly solutions.

Why TPE is Transforming Industries: Key Advantages

Unmatched Processing Efficiency

TPEs require no vulcanization, unlike conventional thermoset rubbers. They melt when heated and solidify upon cooling, allowing for rapid processing via injection molding, extrusion, and blow molding. This results in significantly shorter cycle times, lower energy consumption, and reduced production costs. Scrap and trimmings can be immediately reprocessed, minimizing waste.Superior Design Freedom & Consistency

TPEs offer excellent colorability (including clear and custom colors), consistent batch-to-batch properties, and the ability to manufacture complex, intricate parts with tight tolerances. A major benefit is their ability to be overmolded or co-extruded onto rigid plastics like PP, ABS, or PA, creating superior soft-grip handles, seals, and multi-material components without adhesives.

3. Leading Sustainability Profile

As a 100% thermoplastic and recyclable material, TPE supports circular economy goals. It helps manufacturers comply with stringent international regulations (REACH, RoHS, FDA) and reduces environmental impact. This aligns perfectly with the growing global demand for phthalate-free, latex-free, and eco-conscious materials.

4. Wide Performance Range

TPEs are not a single material but a family of compounds. They are available in a broad spectrum of Shore Hardness (from ultra-soft 10A to semi-rigid 50D), with grades offering enhanced weather resistance, UV stability, chemical resistance, and mechanical strength for specific applications.

When evaluating materials for flexibility, durability, and manufacturability, TPE Rubber stands out as a versatile and intelligent solution. It answers the modern market’s call for high performance, streamlined production, and environmental responsibility. For buyers comparing “TPE vs. Silicone” or “TPE vs. PVC,” TPE often provides the optimal balance of performance, cost, and sustainability.

Keywords for Sourcing: What is TPE, Thermoplastic Elastomer Properties, TPE Material Supplier, Recyclable Rubber, Overmolding TPE, Soft Touch Elastomer, TPE for Injection Molding, Medical Grade TPE, TPE Compounds Manufacturer, Sustainable Elastomer Solutions.

Core Elements of a TPE Rubber Specification:

A robust TPE specification is not a single value but a comprehensive profile of physical, mechanical, and regulatory properties. Key parameters include:

Primary Physical & Mechanical Properties:

Hardness: Defined on the Shore A or Shore D scale (e.g., 50A, 30D). This is the foremost specification, determining feel and flexibility.

Tensile Strength & Elongation at Break: Indicate the material’s strength (MPa/psi) and stretchability (%), crucial for parts under stress.

Compression Set (ASTM D395): A vital metric for sealing applications, measuring permanent deformation after compression. Lower percentages indicate better elastic recovery.

Tear Strength: Resistance to the propagation of a nick or cut.

Performance & Environmental Compliance Data:

Temperature Range: The continuous service temperature span (e.g., -40°C to 135°C) defining operational limits.

Chemical & Fluid Resistance: Specifications for exposure to oils, greases, acids, or alcohols—critical for automotive or industrial uses.

Regulatory Certifications: Compliance with FDA 21 CFR, EU 10/2011 (food contact), USP Class VI, RoHS, REACH, and LFGB standards. These are non-negotiable for medical, food-grade, or consumer goods.

Weathering & UV Stability: Data from tests like ISO 4892 for outdoor applications.

Processing & Quality Assurance Parameters:

Melt Flow Rate (MFR): Governs flow behavior during injection molding or extrusion, impacting production efficiency and part quality.

Specific Gravity: Used for calculating part weight and raw material cost.

Lot-to-Lot Consistency Data: Evidence of manufacturing control ensures predictable performance in high-volume production.

Why Specifications Are Critical for International Procurement

For global buyers, a detailed specification sheet mitigates risk and ensures clarity:

Facilitates Accurate Sourcing: Enables “apples-to-apples” comparison of materials from different global suppliers (TPE manufacturers in Asia, Europe, or North America).

Ensures Product Integrity: Guarantees the material will perform in the end-use environment, preventing costly failures.

Defines Quality Benchmarks: Serves as the contractual basis for quality acceptance and resolves disputes.

Streamlines Development: Accelerates prototyping and approval processes by providing engineers with reliable design data.

Actionable Steps for Buyers

Always request the full Technical Data Sheet (TDS) and Certificate of Analysis (CoA) from your supplier. Cross-reference specification values with your application’s critical-to-quality (CTQ) requirements. For demanding applications, partner with suppliers who offer custom TPE compounding to develop a tailored specification that optimizes performance and cost.

Keywords for Sourcing: TPE Rubber Spec Sheet, TPE Property Table, Thermoplastic Elastomer Hardness Specification, FDA Compliant TPE Data Sheet, TPE Compression Set ASTM, Medical Grade TPE Specifications, TPE Chemical Resistance Chart, Custom TPE Compound Formulation, TPE Material Certification.

How does the cost of TPE compare to traditional rubber (like EPDM or Silicone), and what drives the total cost of ownership?

Can TPE meet stringent regulatory requirements for medical, food-contact, or automotive applications?

What are the key performance limitations of TPE compared to thermoset rubber?

How do we ensure consistent quality and color matching in large-volume orders?

What are the lead times for custom TPE compounds, and how flexible is the supply chain?

1. Consumer Goods & Electronics

TPE is prized for its soft-touch feel, grip enhancement, and aesthetic flexibility.

Handles & Grips: Power tools, kitchen utensils, toothbrushes, and personal care products.

Wearable Devices: Watch bands, fitness tracker housings, and VR headset seals that require skin comfort and durability.

Cases & Protectors: Phone cases, laptop sleeves, and cable jacketing offering impact resistance and tactile appeal.

Seals & Gaskets: In appliances like blenders, coffee makers, and water bottles.

2. Automotive Industry

TPE supports lightweighting, noise reduction, and design integration in modern vehicles.

Interior Components: Soft-touch dashboard panels, cup holder liners, gear shift knobs, and armrest covers.

Sealing Systems: Weather seals, window channels, and lamp gaskets with excellent UV and weather resistance.

Under-the-Hood Parts: Air intake ducts, protective covers, and vibration dampeners (using high-temperature grades).

Exterior Trims: Bumper fascia inserts, stone guards, and aerodynamic body seals.

3. Medical & Healthcare

Medical-grade TPEs meet strict biocompatibility, clarity, and sterilization requirements.

Medical Tubing: IV sets, respiratory masks, catheters, and peristaltic pump tubing.

Device Components: Syringe plungers, inhaler seals, and soft-touch grips on surgical tools.

Wearable Health Tech: ECG patches, drug delivery patches, and ergonomic assistive device handles.

Packaging: Blister packs and seals for medical devices.

4. Industrial & Construction

TPE delivers durability, chemical resistance, and ease of installation in demanding environments.

Hoses & Tubing: Chemical transfer hoses, pneumatic tubes, and water discharge lines.

Gaskets & Seals: Pipe gaskets, tank liners, and waterproofing membranes.

Cable Insulation: Jacketing for industrial cables, solar panel wiring, and data transmission lines.

Anti-Vibration Pads: Machinery mounts and damping components to reduce noise.