What is TPE Rubber? The Complete Guide to Thermoplastic Elastomers Rubber

In today’s rapidly evolving manufacturing landscape, the search for materials that offer flexibility, durability, and sustainability is more critical than ever. Enter TPE rubber – a groundbreaking class of polymers that is redefining what’s possible across industries from automotive to healthcare. But what exactly is TPE rubber, and why is it becoming the material of choice for engineers, designers, and global buyers? In this comprehensive guide, we’ll dive deep into the science, benefits, applications, and future of Thermoplastic Elastomers.

Understanding TPE Rubber: The Hybrid Material Revolution

TPE, or Thermoplastic Elastomer, is neither a traditional rubber nor a conventional plastic – it’s a sophisticated hybrid that combines the best of both worlds. At a molecular level, TPEs consist of hard, crystalline thermoplastic regions and soft, amorphous elastomeric regions. This unique structure gives TPEs the elasticity and softness of vulcanized rubber alongside the processability and recyclability of thermoplastics.

Unlike thermoset rubbers (like EPDM or silicone), which undergo irreversible chemical curing, TPEs can be melted, reshaped, and reprocessed multiple times without significant degradation of properties. This fundamental difference opens up unprecedented opportunities in design, manufacturing efficiency, and environmental responsibility.

Key Types of TPE Materials

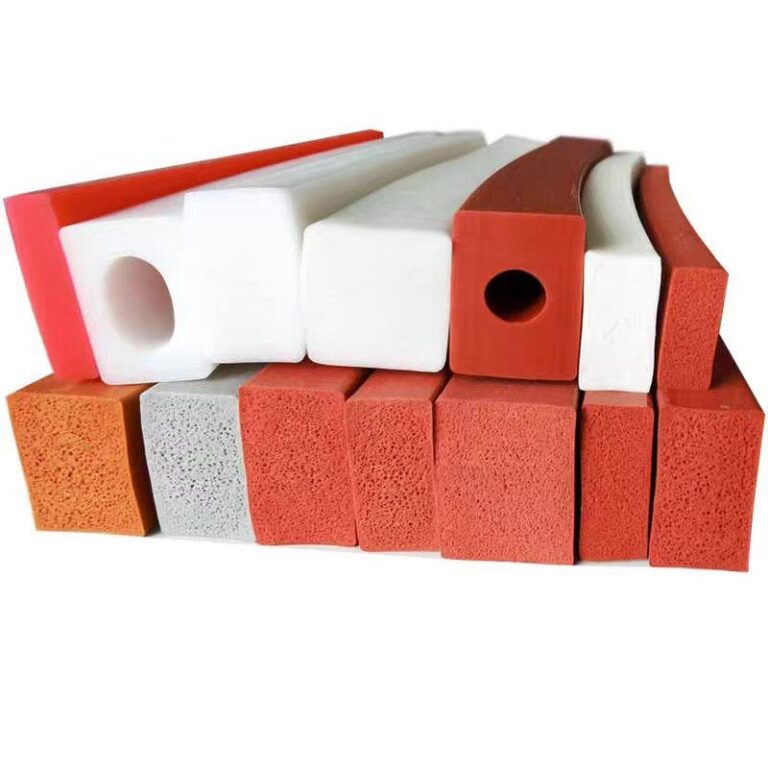

Not all TPEs are created equal. The TPE family includes several key categories, each with distinct characteristics:

-

TPS (Thermoplastic Styrenics): The most common and cost-effective type, often used in consumer products and soft-grip applications.

-

TPO/TPV (Thermoplastic Polyolefins/Vulcanizates): Known for excellent weather and UV resistance, widely used in automotive exteriors.

-

TPU (Thermoplastic Polyurethane): Offers superior abrasion resistance and mechanical strength, ideal for footwear and industrial parts.

-

TPEE (Thermoplastic Polyester Elastomer): Provides exceptional heat and chemical resistance for demanding engineering applications.

-

TPA (Thermoplastic Polyamide): Features high temperature tolerance and oil resistance, suitable for under-hood automotive components.

Why TPE Rubber is Transforming Global Manufacturing

1. Unmatched Processing Efficiency

TPEs eliminate the energy-intensive, time-consuming vulcanization process required for traditional rubbers. They can be processed using injection molding, extrusion, and blow molding equipment with cycle times reduced by up to 50%. This translates to lower production costs, higher throughput, and reduced energy consumption.

2. Superior Design Freedom

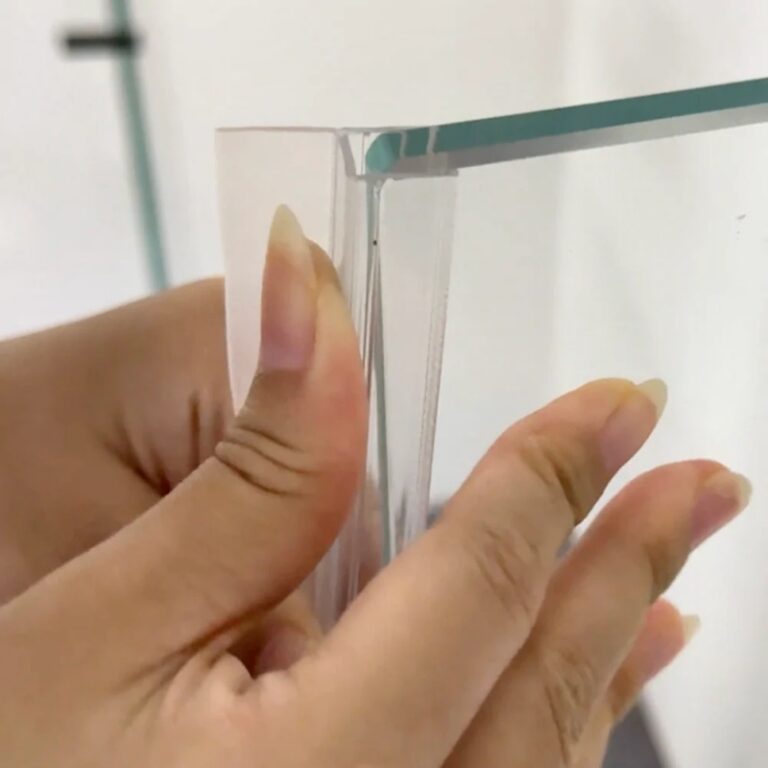

From translucent medical tubing to vibrant tool handles, TPEs offer exceptional colorability and consistency. Their ability to be overmolded onto rigid substrates like PP, ABS, or metals – without adhesives – enables innovative multi-material designs in a single manufacturing step.

3. Environmental Leadership

As a 100% recyclable material, TPE supports circular economy initiatives. Production scrap and end-of-life parts can be reground and reprocessed, dramatically reducing waste. Many TPE formulations are also phthalate-free, latex-free, and comply with REACH, RoHS, and FDA regulations.

4. Performance Versatility

TPEs can be engineered to meet specific requirements:

-

Hardness Range: From ultra-soft 10 Shore A to semi-rigid 50 Shore D

-

Temperature Resistance: Typically -40°C to 120°C (special grades up to 150°C)

-

Chemical Resistance: Formulations available for fuels, oils, and acids

-

Transparency & Biocompatibility: Medical-grade options for healthcare applications

Real-World Applications of TPE Rubber

Automotive Innovation

TPEs are driving lightweighting and sustainability in vehicles. Applications include:

-

Interior soft-touch surfaces and noise-dampening components

-

Weather seals and window channels with excellent UV resistance

-

Under-hood connectors and protective covers

Healthcare Advancements

Medical-grade TPEs enable safer, more comfortable devices:

-

IV tubing sets and respiratory masks

-

Ergonomic grips for surgical instruments

-

Wearable drug delivery patches

Consumer Product Enhancement

From durability to aesthetics, TPEs add value:

-

Soft-grip handles for tools and appliances

-

Waterproof seals for electronics and outdoor gear

-

Sustainable packaging solutions

Industrial Solutions

TPEs deliver reliability in demanding environments:

-

Chemical-resistant hoses and gaskets

-

Cable jacketing for renewable energy systems

-

Vibration-damping mounts for machinery

Selecting the Right TPE: A Buyer’s Checklist

When sourcing TPE materials, consider these critical factors:

-

Performance Requirements: Define operating temperatures, environmental exposure, and mechanical stresses

-

Regulatory Compliance: Verify FDA, USP Class VI, UL, or automotive certifications

-

Processing Method: Ensure compatibility with your molding or extrusion equipment

-

Sustainability Goals: Evaluate recyclability content and carbon footprint data

-

Supplier Capability: Assess technical support, customization options, and global supply chain reliability

The Future of TPE Technology

TPE innovation continues to accelerate, with emerging trends including:

-

Bio-based TPEs: Derived from renewable resources like sugarcane or corn starch

-

Advanced Bonding Grades: For challenging substrates like engineering plastics

-

Smart TPEs: Incorporating conductive or sensing properties

-

High-Performance Grades: Matching specialty elastomers in extreme conditions

Conclusion: Why TPE Rubber is Worth Your Investment

TPE rubber represents more than just another material option – it embodies the future of intelligent, sustainable manufacturing. By offering unparalleled design flexibility, production efficiency, and environmental benefits, TPEs enable companies to create better products while reducing their ecological footprint.

Whether you’re developing the next generation of electric vehicles, life-saving medical devices, or everyday consumer products, TPE rubber provides the performance and versatility needed to succeed in today’s competitive global market.

Ready to explore how TPE rubber can transform your products? Contact our material specialists today for personalized technical consultation and samples tailored to your application requirements.

Keywords for SEO: TPE rubber, thermoplastic elastomer, TPE material properties, TPE vs rubber, TPE applications, medical TPE, automotive TPE, recyclable rubber, overmolding TPE, TPE manufacturing, TPE supplier, sustainable elastomer, TPE grades, thermoplastic elastomer guide