What is EPDM Rubber? The Ultimate Guide to Ethylene Propylene Diene Monomer

In the world of synthetic rubbers, few materials match the remarkable versatility and reliability of EPDM rubber. As industries worldwide demand materials capable of withstanding extreme environments while maintaining cost-effectiveness, EPDM has emerged as a cornerstone material across automotive, construction, industrial, and consumer applications. This comprehensive guide explores why EPDM remains one of the most trusted elastomers globally, its unique properties, and how it continues to evolve to meet modern manufacturing challenges.

Understanding EPDM: The Science Behind the Performance

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber belonging to the polyolefin family, characterized by its saturated polymer backbone. This molecular structure gives EPDM its exceptional resistance to heat, oxidation, and weathering – advantages that distinguish it from other elastomers. The “M-class” rubber designation indicates its classification as a rubber with a saturated chain of polyethylene, offering superior stability compared to unsaturated rubbers like natural rubber or SBR.

The unique formulation of EPDM combines ethylene and propylene with a small percentage of diene monomers, creating cross-linking sites that enable vulcanization. This chemical composition results in a material that maintains flexibility across a wide temperature range while demonstrating outstanding resistance to environmental factors.

Key Properties That Make EPDM Exceptional

1. Unmatched Weather and Ozone Resistance

EPDM’s saturated hydrocarbon backbone makes it virtually immune to ozone cracking and weathering degradation. Unlike many rubbers that deteriorate under UV exposure, EPDM maintains its physical properties for decades, making it ideal for outdoor applications. Independent studies show EPDM roofing membranes can exceed 50 years of service life under proper installation conditions.

2. Superior Temperature Tolerance

EPDM performs consistently across an impressive temperature spectrum:

-

Low-temperature flexibility: Remains elastic down to -40°C (-40°F)

-

High-temperature resistance: Continuous operation up to 150°C (302°F), with intermittent peaks to 175°C

This broad service range surpasses many competing elastomers, particularly in automotive under-hood applications.

3. Excellent Chemical and Water Resistance

EPDM demonstrates remarkable resistance to:

-

Polar fluids (water, steam, alkaline solutions)

-

Hydraulic fluids and brake fluids

-

Dilute acids and bases

-

Alcohols and ketones

While not recommended for petroleum-based oils and fuels, specialized formulations can be developed for specific chemical exposures.

4. Electrical Insulation Properties

With volume resistivity exceeding 10¹⁵ Ω·cm, EPDM serves as an excellent electrical insulator for high-voltage applications, including cable jacketing and transformer components.

Global Applications: Where EPDM Excels

Automotive Industry Leadership

EPDM remains indispensable in vehicle manufacturing:

-

Weatherseals and Sealing Systems: Door seals, window channels, trunk seals, and sunroof gaskets

-

Cooling System Components: Radiator hoses, heater hoses, and thermostat gaskets

-

Vibration Control: Engine mounts and suspension bushings

-

Electrical Systems: Wire harness jacketing and connector seals

Construction and Building Solutions

As a building material, EPDM offers unmatched longevity:

-

Roofing Membranes: Single-ply systems for commercial and residential buildings

-

Expansion Joints and Seals: Bridge deck joints, parking garage seals, and curtain wall gaskets

-

Window and Door Seals: Residential and commercial weatherstripping

Industrial and Manufacturing Applications

-

Conveyor Systems: Belts requiring heat resistance in manufacturing processes

-

HVAC Components: Duct connectors, vibration isolators, and cooling tower fills

-

Pipeline Protection: Anti-corrosion wraps and gaskets for chemical processing

Consumer and Specialty Products

-

Appliance Seals: Refrigerator and dishwasher gaskets

-

Recreational Equipment: Pool liners, marine fenders, and playground surfaces

-

Medical Devices: Pharmaceutical stoppers and respiratory equipment components

EPDM vs. Competing Elastomers: A Comparative Analysis

| Property | EPDM | Silicone | Neoprene | Natural Rubber |

|---|---|---|---|---|

| Max Temp Resistance | 150°C | 230°C | 120°C | 80°C |

| Weather/Ozone Resistance | Excellent | Excellent | Good | Poor |

| Cost Efficiency | High | Medium-High | Medium | Low-Medium |

| Steam/Water Resistance | Excellent | Good | Excellent | Good |

| Compression Set | Good | Excellent | Good | Fair |

Processing and Manufacturing Considerations

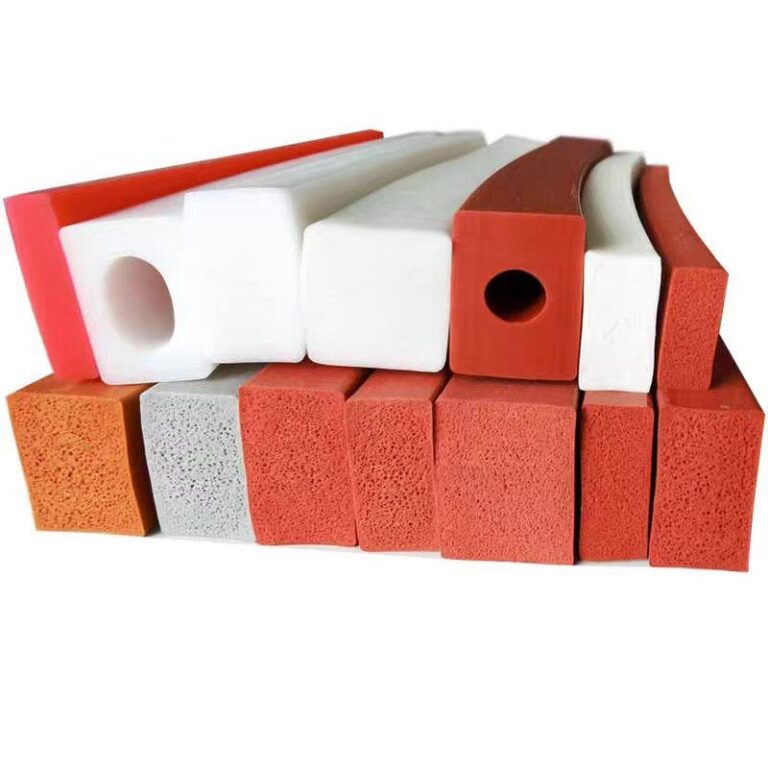

EPDM is typically processed using:

-

Compression Molding: Traditional method for seals and gaskets

-

Injection Molding: For high-volume, complex geometries

-

Extrusion: Continuous profiles for seals and tubing

-

Calendering: Sheet production for roofing membranes

Vulcanization systems for EPDM include sulfur, peroxide, and resin curing, each offering distinct advantages:

-

Sulfur Systems: Cost-effective with good physical properties

-

Peroxide Systems: Superior heat resistance and compression set

-

Resin Systems: Excellent steam resistance for automotive cooling applications

Sustainability and Environmental Profile

Modern EPDM formulations address growing environmental concerns:

-

Recyclability: Post-industrial EPDM can be ground and reused in various applications

-

Long Service Life: Reduced replacement frequency lowers environmental impact

-

Low VOC Emissions: Compliant with automotive and building industry standards

-

RoHS/REACH Compliance: Available in formulations meeting global regulatory requirements

Future Developments and Market Trends

The EPDM industry continues to evolve with several key trends:

-

Enhanced Formulations: Development of self-healing EPDM grades and improved low-temperature flexibility

-

Sustainable Production: Bio-based ethylene from sugarcane and other renewable sources

-

Smart Material Integration: EPDM composites with embedded sensors for condition monitoring

-

Performance Optimization: Nano-reinforced EPDM for improved mechanical properties

-

Circular Economy Initiatives: Advanced recycling technologies for post-consumer EPDM

Selecting the Right EPDM Grade: Technical Considerations

When specifying EPDM for your application, consider these critical parameters:

-

Ethylene Content: Higher ethylene (>60%) improves tensile strength and processability

-

Diene Type: ENB (ethylidene norbornene) offers faster cure rates than DCPD

-

Mooney Viscosity: Affects processing characteristics and finished properties

-

Cure System: Matches application requirements for heat, steam, or chemical resistance

-

Reinforcement: Carbon black vs. mineral fillers for specific performance needs

Conclusion: Why EPDM Remains a Global Industry Standard

For over six decades, EPDM rubber has proven its value across countless applications worldwide. Its unique combination of weather resistance, temperature tolerance, and chemical stability – coupled with excellent cost-performance ratio – ensures its continued relevance in an increasingly demanding market. As manufacturing challenges grow more complex, EPDM’s adaptability through advanced formulations and processing techniques positions it not as a legacy material, but as a forward-looking solution for 21st-century engineering challenges.

Whether you’re sealing a next-generation electric vehicle, protecting a commercial rooftop for decades, or ensuring reliability in harsh industrial environments, EPDM rubber delivers the proven performance that engineers and specifiers trust. Its ongoing evolution through material science innovation promises to extend its applications and performance boundaries for years to come.

Looking for EPDM solutions tailored to your specific requirements? Contact our technical team for comprehensive material selection support, application engineering expertise, and access to our global supply network.

Keywords for SEO: EPDM rubber, ethylene propylene diene monomer, EPDM properties, EPDM vs silicone, EPDM seals, EPDM roofing, automotive EPDM, EPDM gaskets, synthetic rubber, EPDM applications, EPDM temperature range, EPDM chemical resistance, EPDM manufacturing, EPDM suppliers