What Are Silicone Rubber Seal Strips? The Complete Guide for Industrial Buyers

In the world of precision sealing solutions, silicone rubber seal strips stand out as one of the most versatile and reliable materials available today. Whether you’re an engineer designing cutting-edge products or a procurement specialist sourcing sealing components, understanding these flexible strips is crucial for achieving optimal performance, durability, and compliance. This comprehensive guide explores everything you need to know about silicone rubber seal strips – from their fundamental properties to specialized applications and selection criteria.

Understanding Silicone Rubber Seal Strips: Material Science

Silicone rubber seal strips are extruded profiles made from silicone elastomers – synthetic polymers characterized by a backbone of alternating silicon and oxygen atoms, with organic side groups attached. This unique molecular structure gives silicone its exceptional properties that surpass conventional organic rubbers:

-

Temperature Resistance: Continuous performance from -60°C to 230°C (-76°F to 446°F)

-

Chemical Stability: Resistance to ozone, UV radiation, and extreme weather conditions

-

Flexibility Maintenance: Retains elasticity across the entire temperature range

-

Physiological Inertness: Non-toxic and odorless, suitable for food and medical applications

Unlike molded rubber gaskets, seal strips are produced through continuous extrusion processes, allowing for cost-effective production of complex cross-sectional profiles in virtually unlimited lengths. This manufacturing method enables precise customization to meet specific sealing challenges.

Key Properties That Define Performance

1. Exceptional Temperature Range

Silicone seal strips outperform most elastomers in thermal stability. Standard grades operate from -60°C to 230°C, while specialized formulations extend to 300°C (572°F) for brief periods. This makes them ideal for applications spanning cryogenic equipment to high-temperature industrial machinery.

2. Superior Environmental Resistance

Unlike organic rubbers that degrade under UV exposure, silicone maintains integrity through:

-

Ozone and oxygen resistance without adding protective chemicals

-

Weathering stability that ensures decades of outdoor service

-

Moisture resistance without swelling or degradation

3. Compression Set and Elastic Recovery

High-quality silicone seal strips offer compression set values as low as 10-20% (ASTM D395), meaning they maintain sealing force over extended periods and temperature cycles – a critical factor in long-term sealing reliability.

4. Regulatory Compliance

Silicone rubber formulations meet stringent international standards:

-

FDA 21 CFR 177.2600 for food contact applications

-

USP Class VI for medical and pharmaceutical uses

-

NSF/ANSI 51 for food equipment materials

-

RoHS, REACH, and LFGB compliance

Manufacturing Processes and Profile Design

Silicone seal strips are primarily manufactured through hot air vulcanization (HAV) or liquid silicone rubber (LSR) extrusion, each offering distinct advantages:

HAV Extrusion Process

-

Cost-effective for medium to high volumes

-

Wide hardness range (20 to 80 Shore A)

-

Excellent physical properties with good tear strength

-

Color consistency across production runs

LSR Extrusion Process

-

Tighter tolerances (±0.1mm achievable)

-

Superior surface finish without post-treatment

-

Faster production cycles with immediate vulcanization

-

Consistent cross-sectional geometry

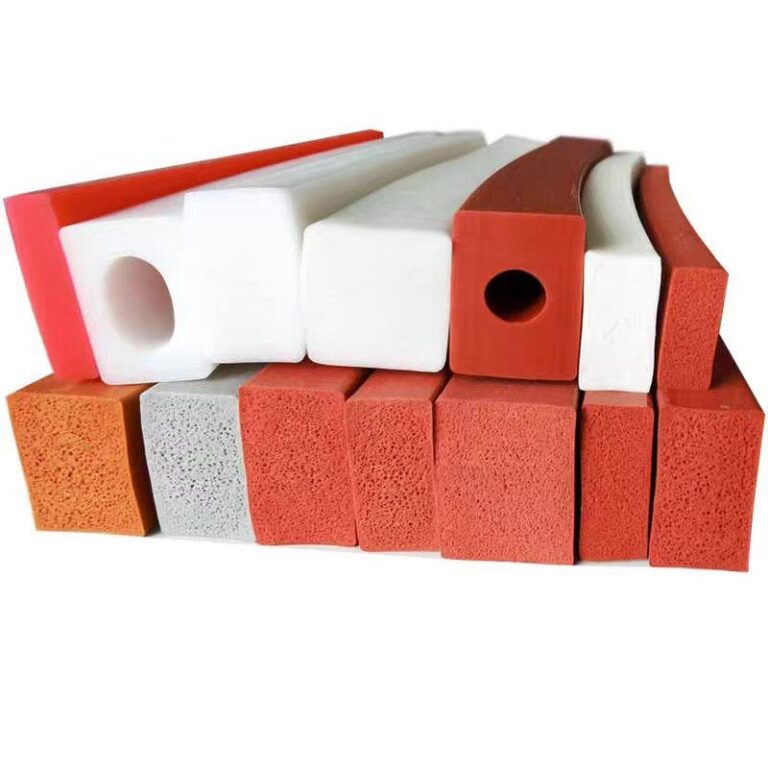

Common Profile Designs

-

Solid D-Profile: Standard weathersealing applications

-

Hollow Tubular: Enhanced compression with lower closure force

-

Complex Multi-Lip: Multiple sealing surfaces in one profile

-

Adhesive-Backed: Pre-applied tape for simplified installation

-

Magnetic-Embedded: Automotive and industrial door seals

Industrial Applications Across Sectors

Automotive and Transportation

-

Vehicle door and window seals with integrated reinforcement

-

HVAC system gaskets in heating and ventilation units

-

Engine compartment seals resistant to oil and temperature extremes

-

EV battery enclosure seals with flame-retardant properties

Construction and Architecture

-

Curtain wall and window glazing gaskets

-

Expansion joint seals for bridges and concrete structures

-

Fire-rated penetration seals (EI 60-120 certification)

-

Greenhouse and conservatory sealing systems

Electronics and Electrical

-

EMI/RFI shielding gaskets with conductive silicone

-

Enclosure seals for outdoor telecommunications equipment

-

NEMA and IP-rated enclosure seals for dust/water protection

-

Heat sink interface materials with thermal conductivity

Medical and Food Processing

-

Cleanroom door and pass-through seals

-

Medical device enclosure gaskets

-

Food processing equipment seals with FDA-compliant formulations

-

Laboratory equipment seals resistant to sterilization processes

Aerospace and Defense

-

Aircraft window and door seals meeting MIL-spec requirements

-

Avionics cooling system gaskets

-

Space vehicle thermal protection system seals

Selecting the Right Silicone Seal Strip: Technical Considerations

Material Grade Selection

-

General Purpose Silicone (VMQ): Standard applications requiring temperature and weather resistance

-

Fluorosilicone (FVMQ): Superior fuel and oil resistance for automotive and aerospace

-

Conductive Silicone: EMI shielding with volume resistivity from 0.1 to 100 ohm-cm

-

High-Temperature Silicone: Specialty grades for continuous 250°C+ applications

-

Low-Temperature Silicone: Maintains flexibility below -70°C for cryogenic uses

-

Platinum-Cured Silicone: Ultra-pure grades for medical and food contact

Performance Specifications

-

Hardness: Typically 30 to 80 Shore A (softer for better sealing, harder for structural applications)

-

Tensile Strength: 8-12 MPa for standard grades, up to 15 MPa for reinforced formulations

-

Elongation at Break: 300-700% depending on compound and reinforcement

-

Tear Strength: 20-50 kN/m for enhanced durability

-

Color Options: Standard (red, black, gray) or custom-matched colors

Design Optimization Factors

-

Compression Ratio: Typically 20-40% for optimal sealing force

-

Contact Pressure: Minimum 0.2 MPa for effective environmental sealing

-

Groove Design: Proper gland dimensions to prevent extrusion or buckling

-

Joint Design: Mitered corners, molded corners, or splice techniques

-

Surface Preparation: Adhesive selection and substrate compatibility

Global Standards and Quality Assurance

Reputable silicone seal strip manufacturers adhere to:

-

ISO 9001:2015 quality management systems

-

ISO/TS 16949 for automotive applications

-

Material traceability from raw silicone to finished product

-

Lot-specific testing including durometer, tensile, and compression set

-

Certified laboratory testing for critical performance parameters

Installation Best Practices

Surface Preparation

-

Clean substrates with isopropyl alcohol or approved cleaners

-

Ensure surfaces are dry, dust-free, and at recommended temperature

-

For adhesive-backed strips, apply firm pressure along entire length

Joint Treatment

-

Mitered joints: Cut at 45° angles for seamless corners

-

Molded corners: Pre-manufactured for complex geometries

-

Splice systems: Chemical or thermal bonding for continuous seals

Compression Guidelines

-

Avoid over-compression beyond design limits

-

Ensure uniform compression along entire seal length

-

Account for thermal expansion in installation dimensions

Sustainability and Environmental Considerations

Modern silicone rubber seal strips contribute to sustainable design through:

-

Long service life reducing replacement frequency and waste

-

Energy efficiency through improved thermal sealing

-

Recyclability initiatives for post-industrial material

-

Low VOC emissions compared to alternative sealants

-

Halogen-free formulations for environmental safety

Future Trends and Innovations

The silicone seal strip industry continues to evolve with several key developments:

-

Smart Sealing Systems: Integration with sensors for condition monitoring

-

Bio-Based Silicones: Developing sustainable raw material sources

-

Nano-Enhanced Formulations: Improved mechanical and barrier properties

-

4D Printing Technologies: On-demand production of complex geometries

-

Self-Healing Silicones: Automatic repair of minor damage during service life

Cost Considerations and Value Analysis

While silicone seal strips typically command a 20-40% premium over conventional rubber alternatives, their total cost of ownership often proves more economical through:

-

Extended service life (often 2-3 times longer than organic rubbers)

-

Reduced maintenance and replacement frequency

-

Energy savings through superior thermal sealing

-

Warranty protection for critical applications

Conclusion: Why Silicone Rubber Seal Strips Deliver Unmatched Value

Silicone rubber seal strips represent the pinnacle of sealing technology, offering unparalleled performance across temperature extremes, environmental challenges, and demanding industrial applications. Their unique combination of material properties, manufacturing flexibility, and long-term reliability makes them an essential component in everything from consumer electronics to aerospace systems.

For procurement specialists and engineers, selecting the right silicone seal strip involves balancing technical requirements, regulatory compliance, and total cost of ownership. By partnering with experienced manufacturers who offer technical support, custom formulation capabilities, and global quality standards, businesses can leverage silicone sealing technology to enhance product performance, ensure regulatory compliance, and achieve sustainable operations.

Ready to optimize your sealing applications with silicone rubber technology? Contact our technical team for expert guidance on material selection, profile design, and application-specific solutions tailored to your unique requirements.

Keywords: silicone rubber seal strips, silicone extrusion profiles, high temperature silicone seals, medical grade silicone gaskets, automotive silicone seals, EMI shielding gaskets, silicone weatherstripping, custom silicone extrusions, FDA silicone rubber, silicone seal strip manufacturers, industrial silicone seals, silicone rubber properties, silicone compression set, liquid silicone rubber extrusion