Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

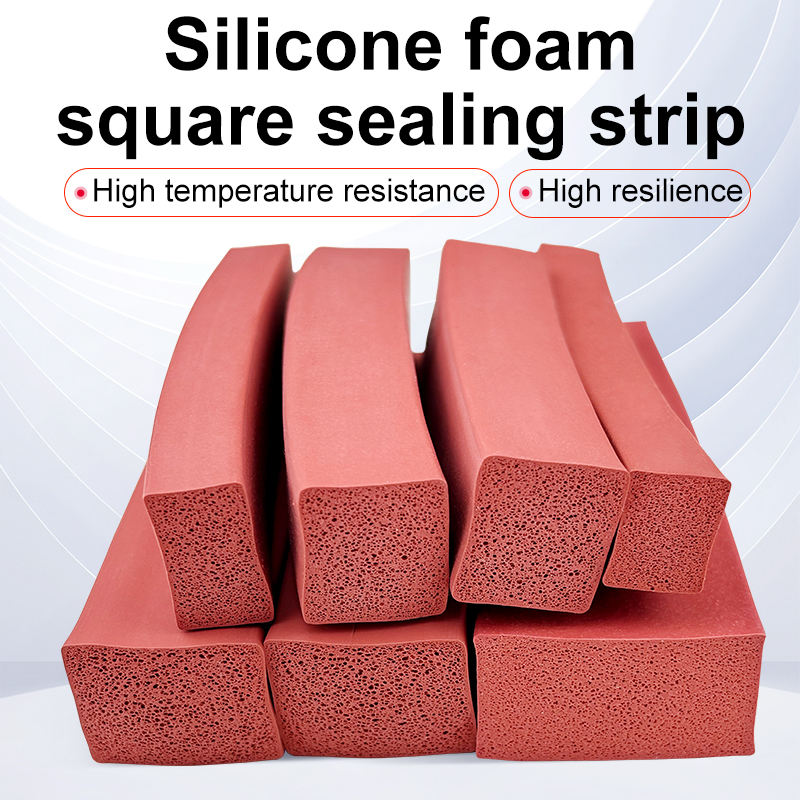

Silicone Foam Seal Strip

Custom Silicone Rubber Foam Sealing Strip Waterproof Silicone Foam Sealing Strip

- 1. Extreme Temperature Tolerance

Seals reliably from -60°C to 230°C - 2. Superior Environmental Protection

Waterproof & dustproof, IP68 certified - 3. Excellent Compression Recovery

Low compression set (<20%), long lifespan - 4. International Safety Certifications

UL 94 V-0, RoHS, REACH compliant - 5. Strong Self-Adhesive Backing

Peel-and-stick, 25N/25mm adhesion - 6. Customization Flexibility

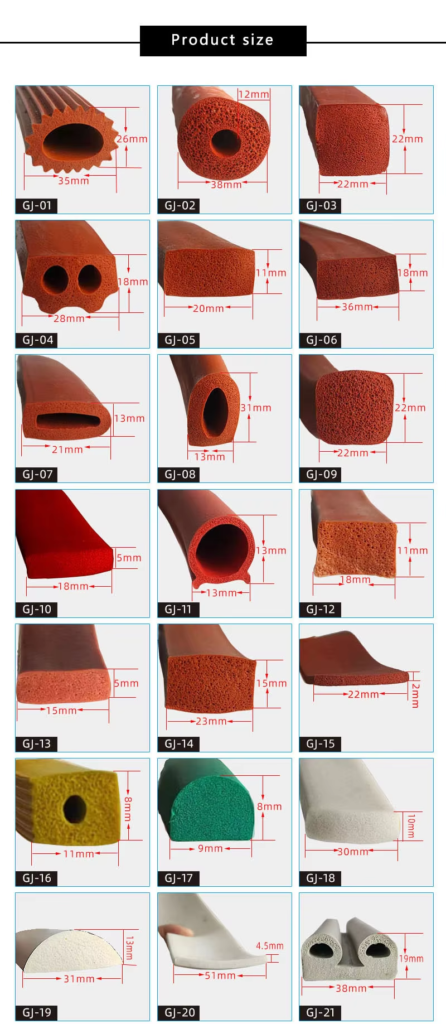

Custom shapes, fast prototyping

A silicone foam sealing strip is a versatile, soft, and compressible gasket material made from silicone rubber processed into a closed-cell foam structure. It is commonly supplied in rolls or strips with a strong self-adhesive backing for easy peel-and-stick installation.

This material is engineered to create a reliable, long-lasting seal against dust, water, air, and moisture. Its closed-cell design means the tiny bubbles inside are sealed, preventing liquids and gases from passing through the material itself. Unlike ordinary rubber or open-cell foam, it offers excellent compression recovery—meaning it bounces back to its original shape after being compressed, maintaining a tight seal over years of use.

The key advantage of silicone foam is its exceptional performance in extreme conditions. It operates reliably in temperatures ranging from -60°C to over 200°C, resisting degradation from UV exposure, ozone, and harsh weather. It is also flame retardant (often UL 94 V-0 certified), making it safe for demanding applications.

Material Properties

Material Grade: Premium Silicone Rubber Foam

Cell Structure: 100% Closed-Cell

Color Options: Black (standard), White, Gray, Custom Colors

Temperature Range: -60°C to +200°C (continuous)

Short-term Exposure: Up to 230°C for 2 hours

Flame Rating: UL 94 V-0 Certified

Compression Set: <20% (ASTM D395, 22hrs @ 70°C)

Density Range: 220-480 kg/m³ (customizable)

Tensile Strength: 0.8-1.2 MPa

Elongation at Break: 200-400%

Adhesive System

Type: High-tack Acrylic Pressure Sensitive Adhesive (PSA)

Alternative: Silicone-based Adhesive (for extreme temp applications)

Peel Strength: 18-25 N/25mm (on stainless steel)

Service Temp with Adhesive: -40°C to +150°C

Release Liner: 80gsm PE Coated Kraft Paper

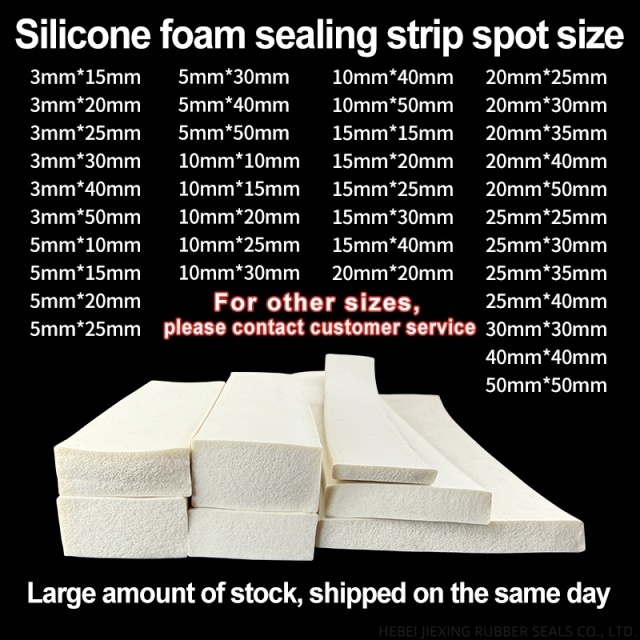

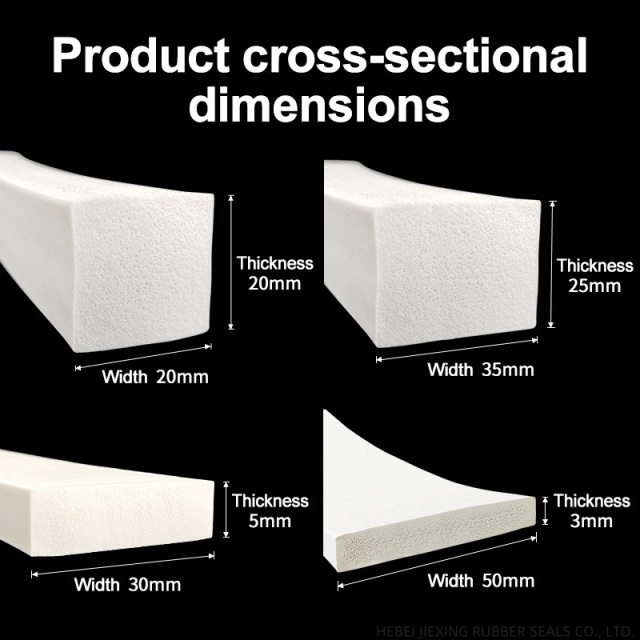

Standard Sizes & Availability

Thickness: 1mm, 2mm, 3mm, 5mm, 10mm (custom 0.5-25mm)

Width: 10mm, 15mm, 20mm, 25mm, 50mm (custom 5-500mm)

Length: 10m, 25m rolls, or custom cut lengths

MOQ: 100 rolls standard sizes, 500m custom sizes

Lead Time: 7-15 days standard, 4-6 weeks custom tooling

What is the typical lead time for custom silicone foam strips?

Can silicone foam strips be painted or color-matched?

What's the difference between "sponge" and "foam" silicone rubber?

Do you provide custom shapes and sizes for specific applications?

Silicone foam strips are used wherever a reliable, durable seal is needed in challenging conditions.

Electronics & Electrical Enclosures: Sealing control panels, junction boxes, LED lights, and outdoor telecom cabinets against dust and water (often to IP ratings).

Automotive: Sealing engine compartments, LED headlights/taillights, battery covers, and HVAC systems against heat, fumes, and noise.

Appliances: Gaskets for ovens, heaters, dishwashers, and other high-temperature appliances.

HVAC & Ducting: Sealing connections in high-temperature air handling systems.

Construction & Glazing: Weatherproofing seals for windows, doors, and curtain walls in demanding architectural projects.

Aerospace & Transportation: Used in cabins, doors, and panels where fire safety and temperature extremes are critical.

Medical Equipment: Sealing for sterilizable equipment and imaging devices due to its cleanliness and stability.