Right Material, Right Seal: An Engineer’s Visual Guide to Rubber Seal Material Selection

By: A Materials Engineer Who’s Fought Seal Failure for 15 Years

Remember that production line shutdown last year due to seal corrosion? Equipment worth millions was idled because a few dollars’ worth of seals swelled and failed in chemical vapor, leading to leaks and a three-day stoppage—direct losses in the hundreds of thousands. This is not an isolated case. In my years on industrial sites, over 60% of seal failures stem not from design flaws, but from incorrect initial material selection.

Choosing the wrong seal material is like fitting a deep-sea submersible with window seals—it might hold temporarily, but failure is inevitable. This article moves beyond generic material lists to provide a practical, actionable three-tier decision framework and indispensable tools to end your selection confusion for good.

Tier 1: Core Decision Dimensions—Ask Yourself These 5 Questions First

Before selecting, answer these questions precisely. This is the starting point for all correct decisions.

-

What media does it contact?

-

A. Air / Water / Steam

-

B. Mineral oils, greases, hydraulic fluids

-

C. Strong acids, alkalis, solvents (e.g., ketones, esters)

-

D. Food, pharmaceuticals, or medical fluids

-

-

What is the temperature environment?

-

A. Ambient (-10°C to 60°C)

-

B. Wide range or thermal cycling (e.g., -30°C to 120°C)

-

C. Continuous high heat (>150°C)

-

D. Extreme cold (< -40°C)

-

-

What is the mechanical stress state?

-

A. Static sealing (e.g., enclosures, doors/windows)

-

B. Dynamic sealing (reciprocating or rotational friction, e.g., shaft seals)

-

C. Long-term compression (e.g., gaskets)

-

-

What are the key performance priorities? (Rank in order)

-

Elastic recovery (low compression set)

-

Abrasion/wear resistance

-

Weather/aging resistance (UV, ozone)

-

Cost control

-

-

Are there special compliance requirements?

Tier 2: Decoding the Material Performance Matrix

The table below is a performance overview of six mainstream rubber seal materials. Ratings are based on typical compounds, with ★★★ indicating optimal performance.

| Performance Dimension | NBR (Nitrile) | EPDM | Neoprene | Silicone | FKM/FPM | PU |

|---|---|---|---|---|---|---|

| Resistance to Oils/Fuels | ★★★ | ★ | ★★ | ★ | ★★★ | ★★★ |

| High-Temp Resistance | ★★(max ~120°C) | ★★★ (max ~150°C) | ★★ (max ~120°C) | ★★★ (max ~230°C) | ★★★ (max ~250°C) | ★★ (max ~100°C) |

| Low-Temp Flexibility | ★★ | ★★ | ★★ | ★★★ | ★ | ★★ |

| Weather/Ozone Resistance | ★ | ★★★ | ★★★ | ★★★ | ★★★ | ★★ |

| Abrasion Resistance | ★★★ | ★★ | ★★ | ★ | ★★ | ★★★ |

| Compression Set Resistance | ★★ | ★★★ | ★★ | ★★★ (HT) | ★★★ (HT) | ★ (HT) |

| Chemical Resistance | ★★ | ★★ | ★★ | ★★ | ★★★ | ★★ |

| Approx. Cost Index | 1.0 (Base) | 1.2 - 1.5 | 1.5 - 2.0 | 3.0 - 6.0 | 8.0 - 25.0 | 2.0 - 4.0 |

Key Takeaway: No material is perfect. EPDM excels in weathering but fails with oils. FKM handles extreme heat and chemicals but is costly and stiff at low temperatures. NBR is the oil-resistant workhorse but ages poorly outdoors. Selection is about matching strengths to your primary challenge.

Tier 3: Scenario-Based “Formula” Recommendations

Let’s translate theory into practice for common, complex scenarios.

Scenario A: Automotive Engine Bay Sealing (Heat + Oil Splash + Vibration)

-

Challenge: Long-term exposure to 130°C+, occasional oil/fuel contact, and constant vibration.

-

Primary Material Choice: ACM (Polyacrylate) or FKM (Fluorocarbon).

-

Why? ACM offers the best cost-to-performance balance for continuous 150°C service with good oil resistance. FKM is the premium choice for higher temperatures or more aggressive synthetic oils.

-

Practical Alternative: HNBR (Hydrogenated Nitrile). A stronger, more heat/oil-resistant upgrade from standard NBR, often a smart compromise.

-

Avoid: Standard EPDM (fails with oil), Standard NBR (limited heat life).

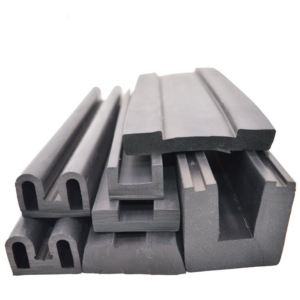

Scenario B: Building Door/Window Seals (Sun, Rain, Wide Temperatures)

-

Challenge: Decades of UV exposure, ozone, rain, and seasonal temperature swings (-40°C to 70°C).

-

Primary Material Choice: EPDM is the undisputed king.

-

Why? Its saturated polymer backbone gives it superior resistance to oxygen, ozone, and UV, the primary causes of outdoor aging. It also maintains flexibility across a wide range.

-

How to Identify Quality EPDM: Don’t just ask for “EPDM.” Specify or verify:

-

Tensile Strength: >12 MPa (indicates good base polymer and reinforcement)

-

Compression Set (22 hrs @ 100°C): <25% (critical for long-term sealing force)

-

Weathering Test Standards: Compliance with ASTM D1149 (ozone) and D925 (staining).

-

Scenario C: Cold Chain/Freezer Seals (-40°C + Frequent Opening)

-

Challenge: Maintaining elasticity and seal force at deep freeze temperatures despite constant door movement.

-

Primary Material Choice: Silicone (VMQ) or Specialty Low-Temp EPDM.

-

Why? Silicone’s low glass transition temperature (Tg) allows it to stay flexible and elastic below -60°C without hardening or cracking. Low-Temp EPDM formulations are a cost-effective alternative for less extreme cycling.

-

Key Metric: Ask for the Low-Temperature Retraction (TR Test, e.g., ASTM D1329) result. A TR10 or TR70 value below your minimum operating temperature is essential.

Scenario D: Food Processing Seals (Heat, Moisture, Grease, Safety)

-

Challenge: Steam cleaning, food-grade lubricants, and non-toxicity/migration compliance.

-

Primary Material Choice: Platinum-Cured Silicone or FDA-Listed EPDM.

-

Why? Platinum-cure silicone leaves no harmful byproducts, has excellent temperature range, and meets FDA, NSF, and EU standards. FDA-listed EPDM is a robust, lower-cost option for many applications.

-

Critical: Never substitute with general-purpose rubbers. Peroxide or sulfur-cured materials can leach harmful substances and taint products. Always request certificates of compliance for specific regulations (FDA 21 CFR §177.2600, NSF/ANSI 51, etc.).

Your Indispensable Practical Tools

Tool 1: Material Selection Decision Flowchart

Follow this logic for a clear path to the right material family.

(Imagine a clear flowchart; described textually below)

-

START: Does the seal contact Petroleum Oils or Fuels?

-

YES -> Go to 2.

-

NO -> Go to 3.

-

-

Will operating temperature consistently exceed 120°C?

-

Is the primary environment outdoor weathering (UV, ozone)?

-

YES -> Go to 4.

-

NO -> Go to 5.

-

-

Is operating temperature consistently below -40°C?

-

YES -> Primary Candidate: Silicone (VMQ).

-

NO -> Primary Candidate: EPDM.

-

-

Are there Food/Medical/Special Compliance needs?

-

YES -> Primary Candidates: Platinum Silicone, FDA EPDM, or Medical FKM.

-

NO -> Go to 6.

-

-

Is extreme high temperature (>200°C) the main factor?

-

YES -> Primary Candidates: Silicone or FKM.

-

NO -> Evaluate based on specific mechanical needs (abrasion, compression set) among NBR, EPDM, CR, or PU.

-

Tool 2: The 7-Point Supplier Communication Checklist

Stop guesswork and wasted time. Provide these details with every inquiry:

-

Temperature Range: Minimum and maximum continuous operating temperatures.

-

Contact Media: Be specific (e.g., “ASTM #3 oil,” “10% saline solution,” “IPA vapor”).

-

Hardness (Shore A): Required range (e.g., 70 ±5 Shore A).

-

Color: For coding or aesthetics.

-

Regulatory Certs: Required standards (e.g., UL94 HB, FDA, NSF 61).

-

Flame Retardancy: If needed (e.g., UL94 V-0).

-

Annual Volume Estimate: Critical for accurate pricing and feasibility.

Industry Insights & Pitfall Avoidance

-

The Total Cost Trap: A cheap NBR seal failing in 6 months outdoors incurs multiple replacement labor costs, far exceeding the initial price of a durable, correctly specified EPDM seal. Think life-cycle cost, not unit price.

-

The Performance Compromise: You must prioritize. Need the chemical resistance of FKM but constrained by budget? A thinner FKM coating on an EPDM core might be a viable hybrid solution. Discuss application compromises with your supplier.

-

Spotting Low-Quality Seals (Quick Checks):

-

Smell: Strong, pungent, or unpleasant odors often indicate excessive use of cheap plasticizers or unreacted chemicals.

-

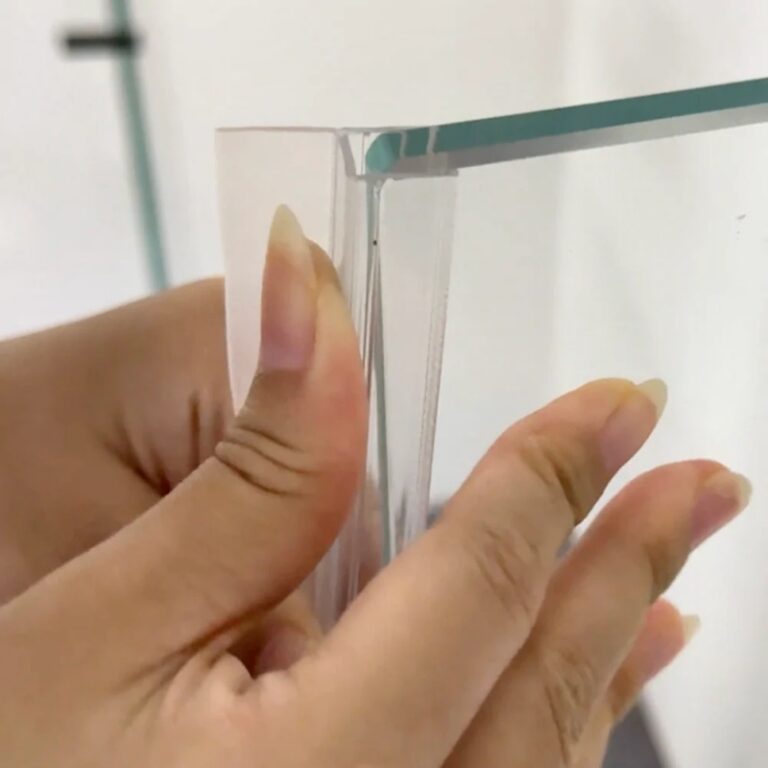

Stretch & Rebound: Gently stretch the seal. A quality compound should feel strong, not easily tear, and snap back quickly without permanent deformation.

-

Cut & Look: Examine the cross-section. It should be uniform, dense, and free of voids, bubbles, or irregularities, indicating poor mixing or molding.

-

Conclusion & Action Plan

The core philosophy is simple: Select by Scenario, Not by Habit.

Stop defaulting to “the usual material.” Use the framework in this guide to systematically define your needs, narrow your options, and communicate effectively with suppliers.

Your Next Steps:

-

Apply the 5 Questions to your current or upcoming project.

-

Download our Decision Flowchart (available on our resources page) and pin it to your workstation.

-

Copy the 7-Point Checklist and use it for your very next supplier RFQ.

By investing minutes in proper selection, you prevent days of downtime, costly replacements, and operational headaches. Choose wisely.

Why This Guide Helps You Make Better Decisions

-

It’s a Decision System, Not a List: We replace overwhelming data with a logical, tiered framework that guides you from problem definition to solution, moving beyond static comparisons to dynamic selection.

-

It Bridges the Gap Between Lab and Field: We translate material properties into real-world scenario-based “formulas” and provide practical tools (checklist, flowchart) for immediate application, addressing the engineer’s core need: “What do I actually specify?”

-

It Imparts Critical, Experience-Based Judgment: We reveal the industry trade-offs and cost traps that only come from years of application experience, empowering you to avoid common, expensive mistakes and make informed compromises.