Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

Rubber Seal Strips for Construction & Building

In the construction industry, rubber seal strips are critical components for ensuring structural integrity, energy efficiency, and long-term durability. Whether for commercial high-rises, residential projects, or industrial facilities, selecting the correct rubber seal material directly impacts a building’s waterproofing, thermal efficiency, acoustic comfort, and maintenance costs. This comprehensive guide analyzes the properties, applications, and value propositions of various rubber seal strip materials for construction, empowering you to make informed procurement decisions tailored to your specific project needs.

Why Rubber Seal Strips Are Critical in the Construction Industry

Core Functions and Value of Building Seals

Rubber seal strips serve multiple essential functions in modern construction:

Weatherproofing and Moisture Protection: High-quality seals prevent water infiltration, reducing structural damage, mold growth, and indoor air quality issues. In regions with extreme weather, this is the first line of defense for protecting building investments.

Thermal Insulation and Energy Efficiency: By filling gaps around windows, doors, curtain walls, and structural joints, rubber seals significantly reduce thermal transfer, lowering heating and cooling costs by up to 20-30% and supporting sustainable building certifications like LEED and BREEAM.

Acoustic Insulation and Sound Control: Specialized rubber compounds dampen vibration and block noise transmission between rooms and from external sources, crucial for residential buildings, hospitals, schools, and offices in urban areas.

Air Infiltration Control and Indoor Air Quality: Seals minimize uncontrolled airflow, preventing dust, pollutants, and allergens from entering while maintaining consistent indoor pressure and ventilation system efficiency.

Structural Movement Accommodation: Buildings naturally expand, contract, and settle. Flexible rubber seals accommodate these movements without compromising the seal integrity, preventing cracks and gaps.

Fire Safety and Smoke Barrier: Certain rubber materials are rated for fire resistance, helping to contain smoke and flames in designated compartments, a critical requirement in commercial and high-rise construction.

Consequences of Incorrect Seal Selection

Choosing the wrong seal material or specification leads to:

Premature seal failure and frequent, costly replacements

Increased energy consumption and operational costs

Water damage, mold remediation expenses, and potential liability

Occupant complaints about drafts, noise, and comfort

Compromised building safety and regulatory non-compliance

Comprehensive Analysis of Rubber Seal Strip Materials for Construction

EPDM (Ethylene Propylene Diene Monomer) Rubber Seals

Overview: The most widely used general-purpose elastomer in construction due to its excellent all-round properties and cost-effectiveness.

Key Properties & Advantages:

Superior Weather Resistance: Exceptional resistance to ozone, UV radiation, and extreme temperatures (-40°C to +120°C continuous).

Excellent Water Resistance: Very low water absorption, ideal for long-term water immersion applications like roofing and below-grade seals.

Good Chemical Resistance: Performs well against mild acids, alkalis, and polar fluids.

Long Service Life: Typically 15-25 years lifespan, offering excellent long-term value.

Cost-Effective: Generally the most economical option for standard applications.

Typical Construction Applications:

Roofing membranes and perimeter seals

Window and door perimeter gaskets

Expansion joint covers

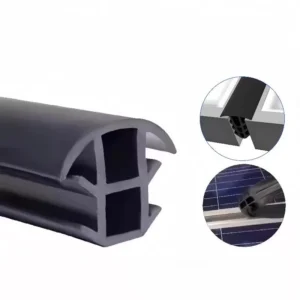

Curtain wall and panel seals

HVAC system gaskets

Value Proposition: Best overall value for most exterior, weather-exposed applications where extreme chemical or fuel resistance is not required.

Silicone Rubber Seals

Overview: A premium material chosen for extreme temperature performance and high flexibility.

Key Properties & Advantages:

Extreme Temperature Range: Outstanding performance from -55°C to +230°C (short-term up to 300°C), suitable for applications near heat sources.

Excellent UV and Ozone Resistance: Maintains properties longer than most organics under constant sun exposure.

High Flexibility and Tear Strength: Remains flexible at very low temperatures, resistant to cracking.

Inert and Hygienic: Does not support microbial growth, suitable for cleanrooms, laboratories, and food processing areas.

Color Stability: Pigments are stable, good for colored architectural applications.

Typical Construction Applications:

High-temperature glazing and lighting seals

Perimeter seals for industrial ovens and HVAC ducts

Sanitary and laboratory sealants

Specialized curtain wall and structural glazing

Expansion joints in extreme climates

Value Proposition: Premium solution for applications with extreme temperatures or where superior long-term flexibility and color retention are critical, despite a higher initial cost.

Neoprene (Polychloroprene) Rubber Seals

Overview: A versatile, medium-performance material known for its good balance of properties and moderate flame resistance.

Key Properties & Advantages:

Good All-Round Resistance: Balanced resistance to oils, fuels, weather, and abrasion.

Moderate Flame Resistance: Self-extinguishing properties make it suitable for certain fire-rated assemblies without added fire retardants.

Good Compression Set Resistance: Maintains sealing force well over time under compression.

Cost-Effective for Mid-Range Needs: More affordable than silicone, often slightly more than EPDM.

Typical Construction Applications:

Electrical enclosure gaskets

Elevator door seals

Seals for areas with occasional oil or solvent exposure

General-purpose door and window gaskets

Vibration isolation pads

Value Proposition: Ideal for indoor or protected applications requiring moderate oil/fuel resistance or inherent flame retardancy at a competitive price.

Nitrile (NBR) Rubber Seals

Overview: The standard material for applications requiring excellent resistance to oils, fuels, and hydrocarbons.

Key Properties & Advantages:

Excellent Oil and Fuel Resistance: Superior to most general-purpose elastomers.

Good Abrasion Resistance: Suitable for dynamic sealing applications with movement.

Good Compression Set and Tensile Strength.

Cost-Effective for Oil/Fuel Applications.

Limitations in Construction:

Poor Weather and Ozone Resistance: Degrades quickly when exposed to sunlight and outdoor elements unless specially compounded (which increases cost).

Limited Temperature Range: Typically -30°C to +100°C.

Typical Construction Applications:

Primarily interior use: Gaskets for generators, fuel storage areas, parking garage equipment, and machinery rooms where oil/fuel contact is possible.

Not recommended for standard exterior building envelope sealing.

Value Proposition: Specialized, cost-effective choice only for specific interior applications involving hydrocarbon exposure. Not suitable for general weatherproofing.

Thermoplastic Elastomers (TPE/TPV)

Overview: A growing class of materials blending polymer and rubber properties, often used as a more recyclable alternative.

Key Properties & Advantages:

Processing Efficiency: Can be extruded and molded like plastic, reducing production costs for complex profiles.

Consistent Quality and Colorability.

Good Weather Resistance (especially TPVs): TPVs (thermoplastic vulcanizates) often match EPDM’s weather resistance.

Recyclability and Sustainability: Scrap can often be reprocessed, appealing for green building projects.

Typical Construction Applications:

Window and door gaskets (increasingly common)

Glass run channels

Modular building seals

Interior trim seals

Value Proposition: A modern alternative offering design flexibility, potential cost savings in complex profiles, and sustainability benefits. Performance varies widely by formulation; TPV is the most weather-resistant subtype.

Comparative Analysis: Material Selection Guide for Construction Buyers

Performance Comparison Table

| Property | EPDM | Silicone | Neoprene | Nitrile (NBR) | TPV (Premium TPE) |

|---|---|---|---|---|---|

| Weather/Ozone Resistance | Excellent | Excellent | Good | Poor | Very Good to Excellent |

| Temperature Range | Very Good (-40°C to +120°C) | Excellent (-55°C to +230°C) | Good (-40°C to +100°C) | Fair (-30°C to +100°C) | Good (-40°C to +135°C) |

| Water Resistance | Excellent | Excellent | Good | Good | Excellent |

| Oil/Fuel Resistance | Poor | Fair | Good | Excellent | Poor to Fair |

| Abrasion Resistance | Good | Fair | Good | Good | Good |

| Compression Set | Good | Fair to Good | Good | Good | Very Good |

| Typical Cost Level | $ | $$$ | $$ | $ | $$ |

Decision Matrix: What to Choose for Your Application

For Standard Windows, Doors, and Curtain Walls:

Primary Recommendation: EPDM. Offers the best balance of weather resistance, lifespan, and cost for 90% of applications.

Consider Silicone if: The project is in an extreme climate (Arctic or desert), involves colored structural glazing, or seals are near intense heat sources.

Consider TPV if: The design requires complex, multi-function profiles or has strong sustainability/recyclability requirements.

For Roofing and Below-Grade Waterproofing:

Primary Recommendation: EPDM. Its exceptional water resistance and durability make it the industry standard for roof membranes, parapet seals, and foundation seals.

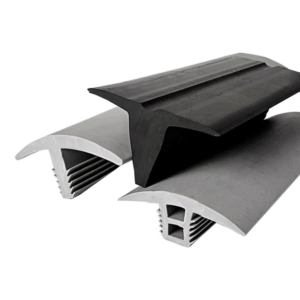

For Expansion Joints and Movement Joints:

For standard vertical/horizontal joints: EPDM or Neoprene for their good movement accommodation and compression set.

For joints in extreme climates or with large movement: Silicone for its superior flexibility across the widest temperature range.

For Areas with Fire Rating Requirements:

Primary Recommendation: Check specific fire test certifications (UL, BS, EN). Neoprene often has inherent resistance. Silicone and specially compounded EPDM can also achieve high ratings. Always request test reports.

For Interior Mechanical/Service Rooms:

For general seals: Neoprene or EPDM.

If oil/fuel spills are possible: Nitrile (NBR) for gaskets on access panels or around equipment. Never use Nitrile for exterior elements.

Key Specification Factors Beyond Material

Density and Hardness (Shore A)

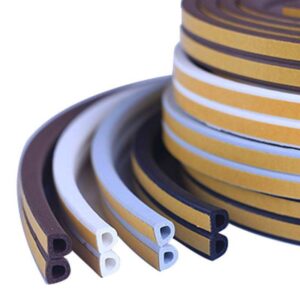

Softer Seals (40-60 Shore A): Better conformability for irregular surfaces, higher compression for sealing large gaps. Used for weather-stripping.

Harder Seals (70-90 Shore A): More structural integrity, better for glazing channels, sliding components, and high-wear areas.

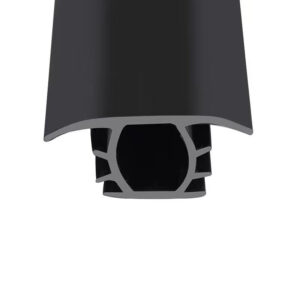

Profile Design

Solid vs. Sponge/Cellular: Solid rubber for dense, high-pressure seals. Sponge rubber (closed-cell) for superior compression and thermal/acoustic insulation.

Profile Shape: U-channel, D-shape, bulb, fin seal, etc. The shape must match the substrate and clamping system. Custom extrusion is available for unique applications.

Adhesion and Installation Method

Self-Adhesive Backing: Convenient for field installation on clean, dry surfaces. Check adhesive type (acrylic, rubber-based) for surface compatibility and temperature limits.

Mechanical Fixing: Clipped, nailed, or screwed into place for more permanent, high-stress applications like windows and curtain walls.

Sourcing Advice for Global Construction Buyers

Requesting Samples and Testing

Always request physical samples of the exact profile and material.

Perform or request simple tests: Check flexibility, compression recovery, and adhesion (if applicable).

Ask for material certification: Ensure the supplier provides a Mill Test Certificate or Compound Data Sheet confirming the material grade (e.g., ASTM D2000 classification for EPDM).

Critical Questions to Ask Your Supplier

Can you provide the specific ASTM, ISO, or BS material standard for this seal?

Do you have test reports for key properties like weathering (ASTM G154), compression set (ASTM D395), or fire performance (UL94, ASTM E84)?

What is the expected service life for this specific application in [your country’s climate]?

Can you supply custom lengths, pre-cut miters, or splicing kits to reduce on-site waste?

What is the lead time for production and shipping to [your location]?

Red Flags in Supplier Proposals

Vague material descriptions like “synthetic rubber” without a specific type (EPDM, Silicone, etc.).

Unusually low prices compared to market averages, which may indicate recycled or substandard compound fillers.

No technical data sheets or unwillingness to provide test certificates.

No experience with projects in your geographical region or similar scale.

Conclusion and Final Recommendations

Selecting the optimal rubber seal strip is a technical decision with long-term financial and performance implications for any construction project.

For most global buyers, EPDM rubber remains the default and most reliable choice for exterior building envelope applications, offering proven performance, durability, and the best overall value.

Invest in silicone when your project faces extreme environmental challenges—severe cold, intense heat, or constant UV exposure—justifying its higher initial cost.

Specify Neoprene or Nitrile for their specific resistance properties (flame or oil) in controlled, interior applications.

Engage with specialized suppliers early in the design process. Provide them with detailed application parameters: location (interior/exterior), temperature range, exposure chemicals, movement requirements, and fire ratings. A reputable supplier will act as a technical partner, guiding you to the most cost-effective, high-performance solution that ensures the longevity, safety, and efficiency of your building.

By understanding the material science and asking the right questions, you can transform rubber seal strips from a simple commodity into a strategic component of high-performance, sustainable construction.

rubber seal strips, construction seals, EPDM vs silicone seal, door and window gaskets, building weatherproofing, expansion joint seal, HVAC rubber seal, neoprene gasket strip, buy rubber seals, international construction materials supplier, and waterproof sealing solutions.