Creat a one-stop cooperative procument service for rubber seal strips

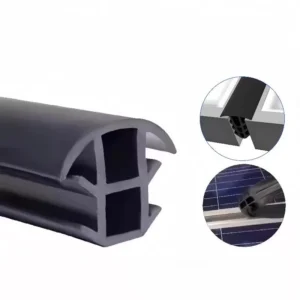

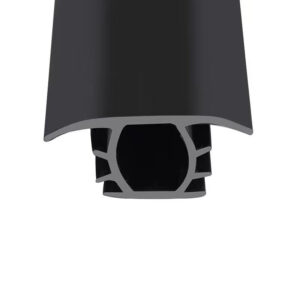

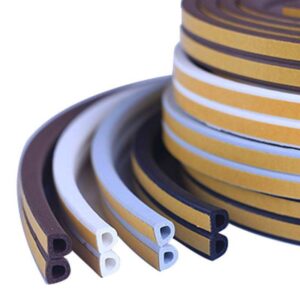

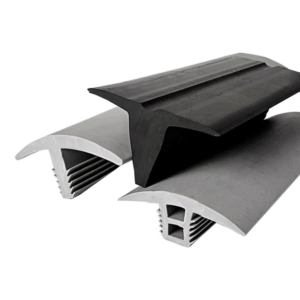

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

Comprehensive Rubber Seal Strips Solutions for Household & Appliance

Rubber seal strips play a crucial role in household and appliance applications, providing essential protection against environmental elements while ensuring optimal performance and energy efficiency. As leading manufacturers and suppliers of premium rubber seals, we offer specialized solutions tailored to meet the diverse needs of global buyers searching for “rubber seal strips,” “appliance gaskets,” “weatherstripping,” and “door seals.” These versatile components serve as critical barriers against moisture, dust, noise, and temperature fluctuations in refrigerators, ovens, washing machines, windows, doors, and various household applications.

Our technical expertise in material science and manufacturing processes ensures that our rubber seal solutions deliver exceptional durability, flexibility, and longevity. With increasing global demand for energy-efficient appliances and sustainable housing solutions, selecting the appropriate rubber seal has become more critical than ever for manufacturers and distributors. This comprehensive guide will help you navigate material options, performance characteristics, and cost considerations to make informed purchasing decisions.

Primary Applications of Rubber Seal Strips in Household & Appliance Sector

Refrigeration and Cooling Appliances

Refrigerator and freezer seals represent one of the most demanding applications for rubber strips in the appliance industry. These seals must maintain consistent compression over thousands of door cycles while withstanding temperature extremes from -20°C to 40°C. Our specialized EPDM and silicone formulations provide excellent low-temperature flexibility and resistance to condensation, mold growth, and household chemicals commonly used in kitchen environments. Proper seal selection directly impacts energy consumption, with high-performance seals reducing compressor workload by up to 15-20%.

Cooking and Heating Appliances

Oven, microwave, and dishwasher seals require materials capable of withstanding high temperatures (up to 300°C for oven applications) while maintaining sealing integrity. Our silicone and fluorosilicone rubber strips offer exceptional thermal stability and resistance to cooking oils, steam, and cleaning agents. These applications demand precise dimensional stability to prevent heat loss and ensure user safety through effective door sealing.

Laundry Appliances

Washing machines and dryers present unique challenges with constant exposure to water, detergents, vibration, and mechanical stress. Our specially formulated EPDM and nitrile rubber seals provide superior resistance to water absorption, detergent chemicals, and mechanical wear. Anti-vibration properties are particularly crucial for reducing operational noise and extending appliance lifespan.

Window and Door Sealing Solutions

Beyond appliances, rubber weatherstripping for windows and doors represents a significant market segment. These applications demand excellent UV resistance, weatherability, and compression set resistance. Our EPDM sponge and dense rubber strips provide decades of reliable service in residential and commercial settings, contributing significantly to building energy efficiency and acoustic insulation.

Material Comparison Guide for Rubber Seal Strips

EPDM (Ethylene Propylene Diene Monomer) Rubber Seals

EPDM represents the most versatile and widely used material for household and appliance seals, particularly valued for applications requiring “weather-resistant rubber seals” and “durable appliance gaskets.”

Properties:

Excellent ozone, UV, and weather resistance

Outstanding thermal stability (-50°C to 150°C)

Good resistance to polar fluids, alkalis, and acids

Superior water and steam resistance

Moderate oil and solvent resistance

Cost-Effectiveness Analysis:

EPDM offers the best balance between performance and cost for most household applications. While initial material costs are 15-20% higher than basic PVC alternatives, the lifespan is typically 3-5 times longer in outdoor applications. For refrigerators and washing machines, EPDM seals maintain compression set properties for 10+ years of daily use, justifying the premium through reduced warranty claims and customer satisfaction.

Optimal Applications: Refrigerator/freezer doors, washing machine lids, window/door weatherstripping, dishwasher surrounds.

Silicone Rubber Seals

Silicone represents the premium choice for high-temperature applications and environments requiring exceptional chemical inertness, often searched as “high-temperature appliance gaskets” and “food-grade silicone seals.”

Properties:

Exceptional temperature range (-60°C to 230°C, special grades up to 300°C)

Excellent ozone and UV resistance

Superior flexibility at low temperatures

Outstanding electrical insulation properties

Food-grade and medical-grade options available

Good resistance to compression set

Cost-Effectiveness Analysis:

Silicone typically costs 2-3 times more than EPDM but offers unparalleled performance in extreme environments. For oven doors and industrial appliances, silicone provides reliable sealing where other materials would degrade rapidly. The investment is justified when failure could result in safety hazards, energy loss, or expensive repairs. For premium appliance brands, silicone seals enhance product positioning and justify higher price points.

Optimal Applications: Oven doors, microwave seals, high-end refrigerator compartments, specialty appliances with extreme temperature requirements.

PVC (Polyvinyl Chloride) and TPE/TPV Seals

PVC and thermoplastic elastomers offer cost-effective alternatives for less demanding applications, commonly marketed as “economical weatherstripping” and “PVC door seals.”

Properties:

Excellent flexibility and processability

Good resistance to water and weathering (stabilized formulations)

Wide range of hardness options

Good compression resistance

Susceptible to UV degradation without proper additives

Cost-Effectiveness Analysis:

PVC seals typically cost 40-60% less than EPDM alternatives, making them attractive for budget-conscious applications. However, lifespan in outdoor applications may be 3-5 years compared to EPDM’s 10-15 years. For indoor applications without UV exposure and temperature extremes, PVC provides adequate performance at minimum cost. TPE/TPV materials bridge the gap between PVC and rubber, offering better elasticity and temperature resistance at a moderate price premium over PVC.

Optimal Applications: Interior door seals, low-cost appliance applications without extreme conditions, temporary weatherproofing solutions.

Neoprene (Chloroprene) Rubber Seals

Neoprene offers a balanced profile with good all-around properties, particularly valued for “flame-resistant appliance gaskets” and “versatile rubber weatherstripping.”

Properties:

Good resistance to oils, fuels, and chemicals

Moderate weather and ozone resistance

Excellent flame resistance

Good physical toughness and tear resistance

Moderate temperature range (-40°C to 120°C)

Cost-Effectiveness Analysis:

Priced between EPDM and silicone, neoprene provides specialized properties that justify its use in specific applications. Its inherent flame resistance eliminates the need for expensive additives required by other materials. For appliances requiring UL certification or specific flame ratings, neoprene often represents the most cost-effective compliant solution.

Optimal Applications: Electrical appliance seals requiring flame resistance, garage door seals, applications requiring oil resistance.

Foam Rubber and Sponge Seals

Closed-cell and open-cell foam materials provide superior compressibility and sealing at low closure forces, searched as “compressible weatherstripping” and “foam tape seals.”

Properties:

Excellent compressibility and conformability

Good acoustic and thermal insulation

Lightweight with low material usage

Variety of density options for specific compression requirements

Generally lower durability than solid rubber

Cost-Effectiveness Analysis:

Foam seals offer the lowest material cost per linear foot but may require more frequent replacement in high-use applications. Their superior sealing at minimal compression force makes them ideal for applications where door/window alignment cannot be precisely controlled. For retrofit and DIY markets, foam tapes with adhesive backing provide installation savings that offset material limitations.

Optimal Applications: Irregular surface sealing, acoustic insulation, low-pressure closure applications, temporary seals.

Performance Factors and Selection Criteria

Compression Set Resistance

Compression set measures a material’s ability to return to its original thickness after prolonged compression. This critical property determines seal longevity in appliance doors that remain closed for extended periods. EPDM and silicone typically offer the best compression set resistance (15-25% set after 22 hours at 70°C), while PVC and foam materials may exhibit 40-60% set under the same conditions. For refrigerator and oven doors, materials with compression set below 30% are essential for maintaining energy efficiency throughout the product lifespan.

Temperature Tolerance

Different household environments present varying thermal challenges. Consider these guidelines:

Freezer compartments: -30°C to 0°C (silicone or specialty EPDM)

Refrigerator doors: 0°C to 40°C (EPDM or quality PVC)

Oven doors: 100°C to 300°C (silicone or fluorosilicone)

Dishwasher surrounds: 60°C to 90°C with steam (EPDM or silicone)

Window/door weatherstripping: -40°C to 70°C (EPDM or neoprene)

Chemical and Environmental Resistance

Consider the specific exposures in each application:

Kitchen appliances: Cooking oils, fats, acids, alkalis, cleaning agents

Laundry appliances: Detergents, bleaches, fabric softeners, hot water

Outdoor applications: UV radiation, ozone, rain, pollutants, temperature cycling

Bathroom applications: High humidity, mold growth, cleaning chemicals

Durability and Lifespan Expectations

Material selection directly impacts product longevity and warranty considerations:

Premium silicone: 10-15 years in high-temperature applications

Quality EPDM: 8-12 years in weather-exposed applications

Neoprene: 5-10 years depending on environmental conditions

PVC: 3-7 years with UV stabilization

Foam materials: 2-5 years in compression applications

Regional Considerations for Global Buyers

Climate-Specific Recommendations

Different geographical regions present unique challenges for rubber seals:

Tropical/Humid Climates (Southeast Asia, Latin America):

High humidity and UV intensity demand materials with excellent mold resistance and UV stability. EPDM with carbon black provides optimal performance. Silicone offers superior mold resistance but at higher cost.

Cold Climates (Northern Europe, Canada, Northern US):

Low-temperature flexibility becomes critical. Silicone maintains flexibility down to -60°C, while specialty EPDM formulations perform well to -50°C. PVC becomes brittle below -10°C and should be avoided.

Arid/Desert Climates (Middle East, Australia, Southwestern US):

Extreme UV exposure and temperature swings (up to 70°C differential between day and night) require materials with exceptional UV and thermal cycling resistance. EPDM with UV stabilizers or silicone provide the best performance.

Marine/Coastal Environments:

Salt spray and high humidity accelerate degradation of many materials. EPDM offers excellent saltwater resistance, while neoprene provides good balance of properties at moderate cost.

Regulatory and Certification Requirements

Global buyers must consider regional regulations:

European Union: REACH compliance, RoHS directives, specific material restrictions

United States: UL certification for flame resistance, FDA compliance for food contact applications

Asia-Pacific: Varying national standards, with increasing emphasis on environmental compliance

Global Standards: ISO 9001 manufacturing quality, ISO 14001 environmental management

Cost-Benefit Analysis and Value Optimization

Total Cost of Ownership Analysis

When evaluating rubber seal options, consider the complete cost picture:

Material-Only Comparison (Cost per linear meter):

PVC: $0.50-$1.50

EPDM: $1.50-$3.50

Neoprene: $2.00-$4.00

Silicone: $3.00-$8.00

Installation and Processing Costs:

Some materials require specialized adhesives or surface preparations. EPDM and silicone typically bond well with standard adhesives, while PVC may require primers. Silicone’s non-stick properties can complicate automated installation.

Failure and Replacement Costs:

Consider warranty claims, service calls, and brand reputation damage from premature seal failure. A $2 savings on material that leads to a $150 service call represents poor value engineering.

Energy Efficiency Impact:

High-performance seals directly reduce energy consumption in refrigerators and building envelopes. EPDM refrigerator door seals typically pay back their premium over PVC through energy savings within 2-3 years of operation.

Value Engineering Recommendations

Based on application requirements, we recommend:

Best Value for Most Applications: Quality EPDM provides optimal balance of performance, durability, and cost for 80% of household and appliance applications.

Premium Applications Where Justified: Silicone for extreme temperatures, food contact, or where brand positioning supports premium pricing.

Budget Solutions with Understood Limitations: PVC for interior applications without UV exposure or temperature extremes, with clear communication of expected lifespan.

Specialized Applications: Neoprene for flame resistance requirements, foam for irregular surfaces or acoustic applications.

Customization and Manufacturing Capabilities

Our manufacturing facilities support complete customization to meet specific application requirements:

Profile Extrusion: Custom die development for unique cross-sectional designs

Material Formulation: Proprietary compounds optimized for specific performance requirements

Secondary Operations: Cutting, splicing, adhesive application, packaging

Quality Assurance: 100% dimensional inspection, material verification, performance testing

Logistics Support: Global shipping, customs documentation, just-in-time delivery

Sustainability and Environmental Considerations

Modern rubber seal production incorporates sustainable practices:

Material Selection: REACH-compliant formulations, recyclable materials where possible

Manufacturing Efficiency: Energy-efficient processes, material waste minimization

Product Longevity: Designing for extended service life reduces replacement frequency

End-of-Life Considerations: Guidance on proper disposal and potential recycling options

Conclusion and Purchasing Guidance

Selecting the optimal rubber seal requires balancing performance requirements, environmental conditions, regulatory compliance, and total cost considerations. For most household and appliance applications, EPDM represents the ideal balance of properties and value. Silicone justifies its premium in extreme temperature applications, while PVC serves cost-sensitive applications with understood limitations.

Our technical team provides application-specific recommendations to ensure optimal performance and value. Contact us with your specific requirements for customized solutions, samples, and competitive quotations for your rubber seal needs in the household and appliance sector.