Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

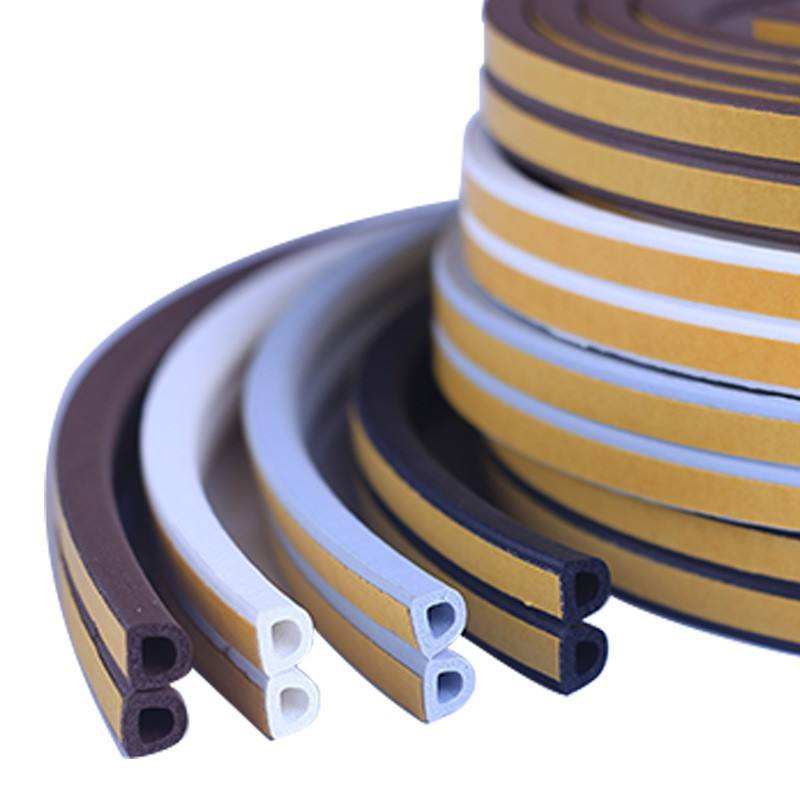

Rubber Door Seal Strip

Premium Rubber Seal Strips for Superior Sealing Performance

Brand: Custmized

Product Origin: China

Delivery: 5-15 day

Supply capacity: 1000/month

-

Excellent Weather Resistance – Withstands extreme temperatures from -40°C to 82°C.

-

Superior Soundproofing – Reduces noise effectively for a quieter indoor environment.

-

Strong Adhesive Backing – Easy peel-and-stick installation with durable, long-lasting bond.

-

Durable & Long-Lasting – Premium EPDM material ensures flexibility and years of reliable service.

-

Energy Saving – Creates airtight seal to lower heating and cooling costs.

Product Overview & Key Advantages

Rubber Seal Strip | Yichang Rubber

Our high-performance rubber seal strips provide reliable protection against drafts, moisture, dust, and noise. Engineered with precision and durability in mind, these versatile sealing solutions are ideal for residential, commercial, and automotive applications. Manufactured from premium-grade materials, our seals maintain flexibility across temperature extremes while offering long-lasting performance.

Key Features and Advantages

Exceptional Durability

UV-resistant formulation prevents cracking and degradation from sun exposure

Temperature tolerance from -40°F to 180°F (-40°C to 82°C)

Maintains elasticity through seasonal changes for consistent performance

Superior Sealing Performance

Multi-chamber design creates airtight and watertight barriers

Excellent compression recovery ensures continuous seal integrity

Reduces energy costs by preventing air leakage

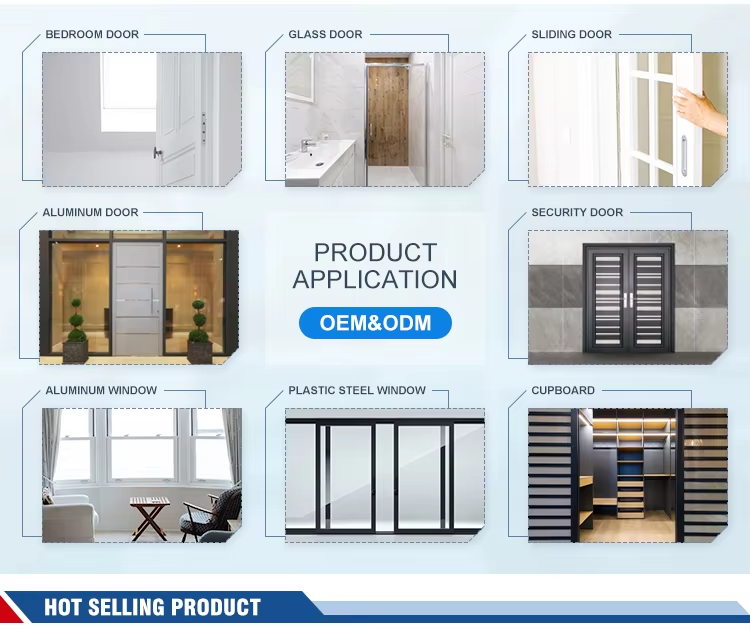

Versatile Application

Compatible with various surfaces including wood, metal, vinyl, and glass

Suitable for interior and exterior applications

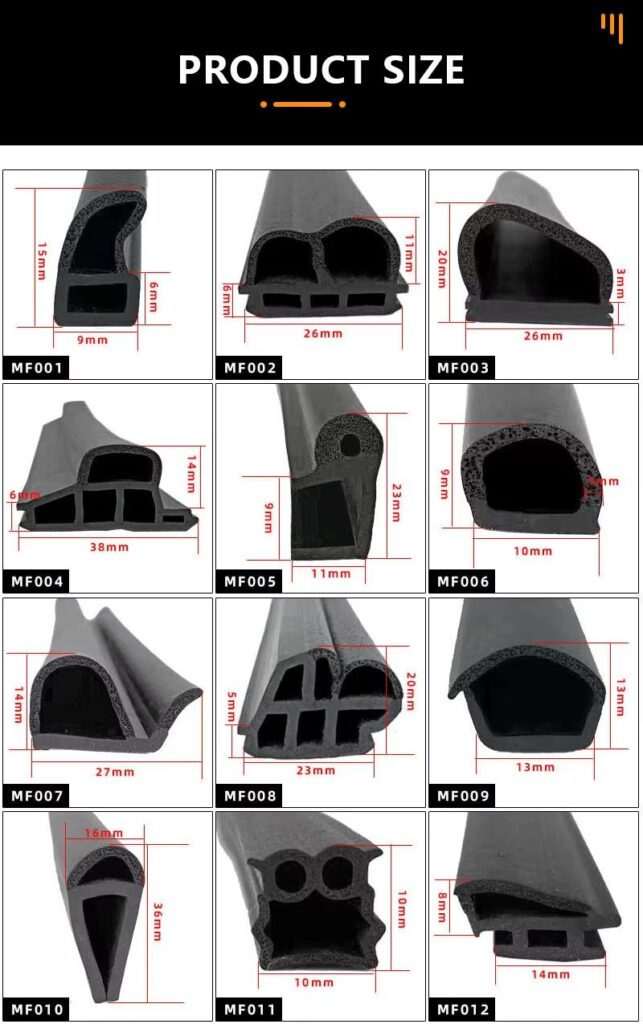

Multiple profiles address different sealing requirements

Easy Installation & Maintenance

Self-adhesive backing with strong acrylic adhesive

Simple peel-and-stick application requires no special tools

Easy to clean with standard household cleaners

Technical Specifications

Standard Rubber Seal Strip Specifications

Parameter | Specification | Details |

|---|---|---|

| Material | EPDM Rubber | Ethylene Propylene Diene Monomer |

| Density | 1.2 g/cm³ | Consistent material density |

| Hardness | 65 ± 5 Shore A | Optimal balance of flexibility & rigidity |

| Tensile Strength | ≥ 12 MPa | High resistance to stretching |

| Elongation at Break | ≥ 300% | Excellent flexibility |

| Temperature Range | -40°C to +82°C | Wide operational tolerance |

| Adhesive Type | Acrylic Pressure-Sensitive | Strong, durable bonding |

| Color Options | Black, Brown, Gray, White | Standard and custom colors |

Available Dimensions

| Application Type | Width Range | Thickness Range | Standard Length |

|---|---|---|---|

| Door Seals | 10mm - 50mm | 3mm - 12mm | 10m, 20m rolls |

| Window Seals | 8mm - 30mm | 2mm - 8mm | 5m, 10m rolls |

| Shower Door Seals | 6mm - 25mm | 4mm - 10mm | 3m, 5m rolls |

| Automotive Seals | 5mm - 40mm | 3mm - 15mm | Various lengths |

| Custom Profiles | 5mm - 100mm | 1mm - 20mm | Customizable |

Common Applications & Uses

Residential & Commercial Uses

Window Sealing: Create airtight seals around residential and commercial windows

Door Weatherproofing: Seal gaps around exterior and interior doors

Shower & Bathroom: Water containment for shower doors and bathroom fixtures

HVAC Systems: Seal ductwork and ventilation systems

Automotive & Industrial Uses

Vehicle Door Seals: Weatherproofing for car, truck, and RV doors

Industrial Equipment: Seal machinery enclosures and control panels

Marine Applications: Waterproof seals for boats and marine equipment

Specialized Applications

Soundproofing: Reduce noise transmission between rooms

Dust Prevention: Create dust barriers in workshops and clean rooms

Energy Efficiency: Improve insulation in green building projects

Proper Usage Guidelines

Preparation

Clean the application surface thoroughly with isopropyl alcohol

Ensure surface is dry, smooth, and free of debris

Measure and cut rubber strips to required length

Installation Process

Peel protective backing from adhesive side

Align strip carefully with application area

Apply moderate pressure along entire length

Use a roller tool to ensure proper adhesion

Post-Installation

Allow 24 hours for adhesive to reach full strength

Avoid exposing to moisture during curing period

Test seal effectiveness after full adhesion

Frequently Asked Questions (FAQ)

How do I choose the right rubber seal strip for my windows?

Are these seal strips suitable for exterior doors in cold climates?

How long does the adhesive backing last?

Can the strips be painted to match my decor?

How do I clean and maintain rubber seal strips?

What is the expected lifespan of your rubber seals?

Trust & Quality Assurance

Manufacturing Standards

ISO 9001:2015 certified production facilities

Each batch undergoes pressure, flexibility, and leak testing

Raw materials sourced from audited suppliers

Traceability codes on every hose segment

Warranty & Support

5-year warranty against manufacturing defects

24-month warranty on fittings and couplings

Technical support available via email, chat, and phone

Comprehensive installation guides and videos

Customer Support

Technical assistance for application questions

Sample program for testing compatibility

Custom fabrication available for large projects

Ordering Information

Minimum order quantity: 10 meters for standard profiles

Custom profiles available with 50-meter minimum

Samples available for testing and verification

Bulk pricing for commercial and contractor accounts

Worldwide shipping with order tracking