Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

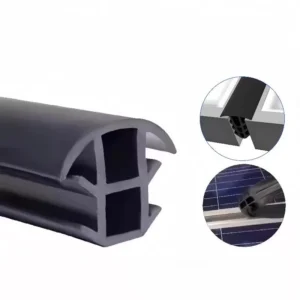

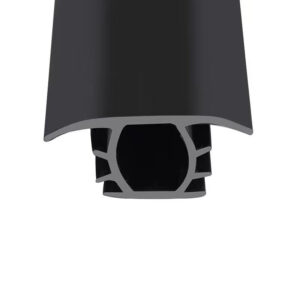

Special Shaped Rubber Seal Strips

High-Performance Special Shaped Rubber Seal Strips for Precision Sealing

Brand: Custmized

Product Origin: China

Delivery: 5-15 day

Supply capacity: 1000/month

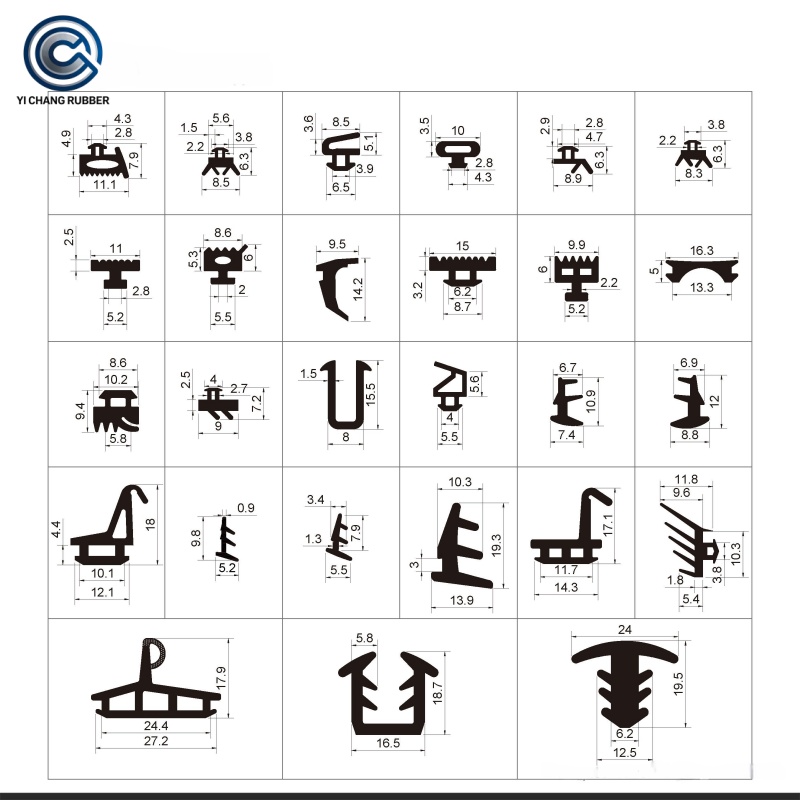

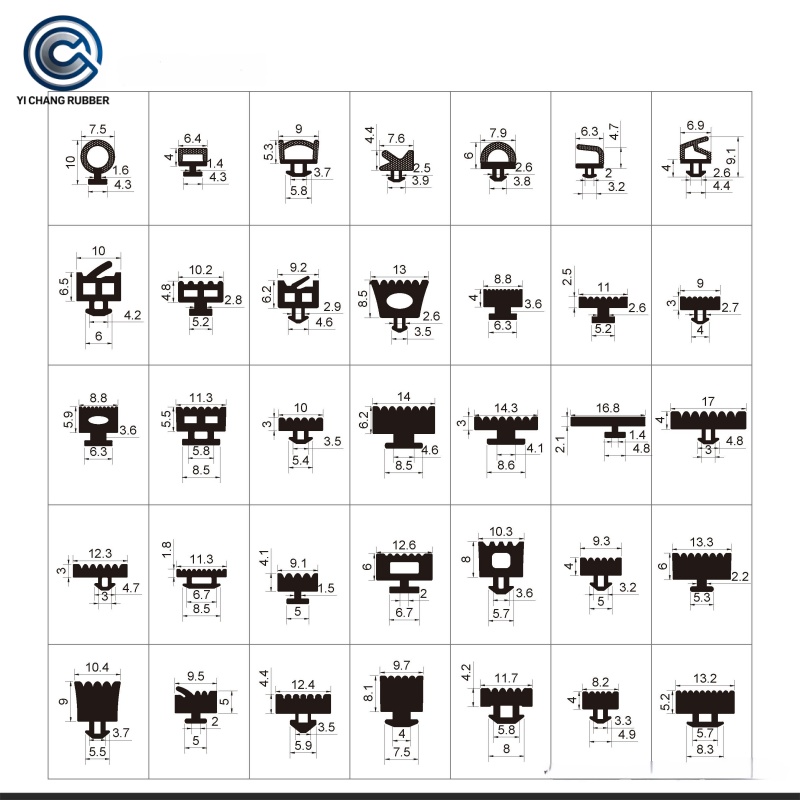

- Precision T/U/D Profiles – Exact fit for specific channels and grooves.

- Superior Weather Resistance – Withstands UV, ozone, and extreme temperatures.

- Multiple Material Options – EPDM, silicone, neoprene, and PVC available.

- Easy Press-Fit Installation – Designed for quick and secure application.

- Custom Extrusion Service – Tailored sizes, hardness, and colors on request.

Product Overview & Key Advantages

Our specialized T, U, and D-shaped rubber seal strips are engineered to provide reliable, long-lasting seals against environmental elements. Ideal for industrial, automotive, marine, and construction applications, these extruded profiles offer tailored solutions for gaps, edges, and channels where standard seals fall short. We combine advanced polymer compounds with precision manufacturing to deliver superior performance.

Optimized Seal Design: The distinct T, U, and D cross-sections are crafted to fit specific grooves and surfaces, ensuring maximum contact and sealing pressure for enhanced protection against dust, water, air, and noise.

Superior Material Selection: Available in EPDM (excellent weather/ozone resistance), Silicone (high-temperature), Neoprene (oil & flame resistant), and PVC, ensuring compatibility with your operating environment.

Exceptional Durability: Our compounds resist UV radiation, extreme temperatures (-60°C to 300°C range available), oxidation, and corrosion, guaranteeing a long service life and reducing replacement frequency.

Easy Installation & Flexibility: Designed for simple press-fit or adhesive-back installation into corresponding channels. The material flexibility allows for smooth application on curved or straight surfaces.

- Customization Ready: Beyond standard sizes, we specialize in custom extrusion. We can adjust dimensions, hardness (Shore A), color, and material to meet your exact OEM or project specifications.

Profile Shape | Key Dimensions (A x B x C)* | Standard Length | Available Materials | Hardness (Shore A) | Color |

|---|---|---|---|---|---|

| T-Shaped Seal | 6mm x 10mm x 3mm (Stem x Top x Leg) | 10m / 20m / 50m rolls | EPDM, Silicone, PVC | 50±5, 60±5, 70±5 | Black, White, Gray |

| U-Shaped Seal (Channel) | 10mm (H) x 5mm (W) x 2mm (Thickness) | 10m / 20m / 50m rolls | EPDM, Neoprene, PVC | 40±5, 50±5, 60±5 | Black, Custom |

| D-Shaped Seal (Bulb) | 8mm (Dia.) x 5mm (Base Width) | 10m / 20m / 50m rolls | EPDM, Silicone | 30±5, 40±5, 50±5 | Black, White |

Common Applications & Uses

T-Shaped: Perfect for insertion into T-slots in panels, machinery guards, and assembly lines. Commonly used in cabinet sealing, electronic enclosures, and automotive trim fixation.

U-Shaped/U-Channel: Ideal for wrapping and protecting the edges of glass, metal sheets, and automotive doors/windows. Provides a secure grip and cushioning.

D-Shaped/ bulb seals: Excellent for compressing against flat surfaces to create an airtight/watertight barrier. Widely used in refrigerator doors, industrial ovens, sealing hatches, and HVAC systems.

Proper Usage Guidelines

Surface Preparation: Ensure the mounting surface is clean, dry, and free of oil, dust, or old adhesive residue.

Measurement & Cutting: Measure the required length accurately. Use a sharp blade or scissors for a clean, straight cut.

Installation:

For T-strips, align and press firmly into the matching T-slot channel.

For U-channels, align over the edge and press evenly along its length.

For D-strips (often with adhesive backing), peel the liner and press the seal onto the surface, starting from one end.

Joining Ends: For continuous sealing, cut ends at a 45° angle and butt them together tightly. For critical seals, a compatible adhesive can be applied at the joint.

Frequently Asked Questions (FAQ)

What is the best material for outdoor use in all weather conditions?

Can I get these seals with an adhesive backing?

Do you offer custom colors and minimum order quantities (MOQ)?

Do you offer custom lengths or specialized fittings?

How do I choose the right hardness (Shore A)?

What are your lead times for samples and bulk orders?

Trust & Quality Assurance

Manufacturing Standards

ISO 9001:2015 certified production facilities

Each batch undergoes pressure, flexibility, and leak testing

Raw materials sourced from audited suppliers

Traceability codes on every hose segment

Warranty & Support

5-year warranty against manufacturing defects

24-month warranty on fittings and couplings

Technical support available via email, chat, and phone

Comprehensive installation guides and videos

Customer Feedback

“Used these rubber seals in our manufacturing plant for 3 years with zero failures” – Industrial customer testimonial

“Perfect for rubber seals animation projects – flexible yet holds shape” – Animation studio feedback

98.2% positive feedback from 850+ wholesale customers

Why Choose Our Special Shaped Seals?

Precision Engineering: Every extrusion is manufactured to tight tolerances for consistent performance.

Technical Support: Our engineering team provides application-specific guidance to help you select the optimal profile and material.

Quality Assurance: Rigorous testing for dimensions, physical properties, and environmental resistance ensures compliance with our high standards.

Global Export Expertise: We are experienced in packaging and documentation for seamless international shipping to your destination.