How do you seal the gap between solar panels? Solutions for Waterproof, Durable, and Cost-Effective Photovoltaic Module

High-Performance Rubber Sealing Solutions for Photovoltaic Modules

In the rapidly evolving solar energy industry, ensuring the long-term durability and efficiency of photovoltaic installations has become paramount. One critical component often overlooked is the rubber sealing strips for photovoltaic modules that protect systems from environmental damage. At the heart of every reliable solar array lies a simple yet crucial element: the solar panel rubber seal strip that prevents water ingress, dust accumulation, and thermal stress damage. This comprehensive guide explores the optimal sealing solutions for solar panel gap sealing, helping you make informed decisions about EPDM gasket for solar panels, solar panel T-gaskets, and other specialized sealing products that ensure your investment delivers maximum returns for decades.

Why Proper Sealing Between Solar Panels Matters

The Critical Role of Solar Panel Sealing Systems

Photovoltaic modules face relentless environmental challenges—from torrential rains and humidity to UV radiation and temperature extremes. Without proper sealing between solar panels, moisture infiltration can lead to:

- Corrosion of electrical connections

- Reduced energy output and efficiency losses

- Potential electrical safety hazards

- Voided manufacturer warranties

- Premature system failure requiring costly replacements

The best sealing strip for gaps in photovoltaic solar panels serves as the first line of defense, creating a continuous barrier that protects the vulnerable interfaces between panels, frames, and mounting systems.

Common Points of Vulnerability in Solar Arrays

Solar installations typically develop leaks at several critical junctions:

- Inter-panel gaps where adjacent modules meet

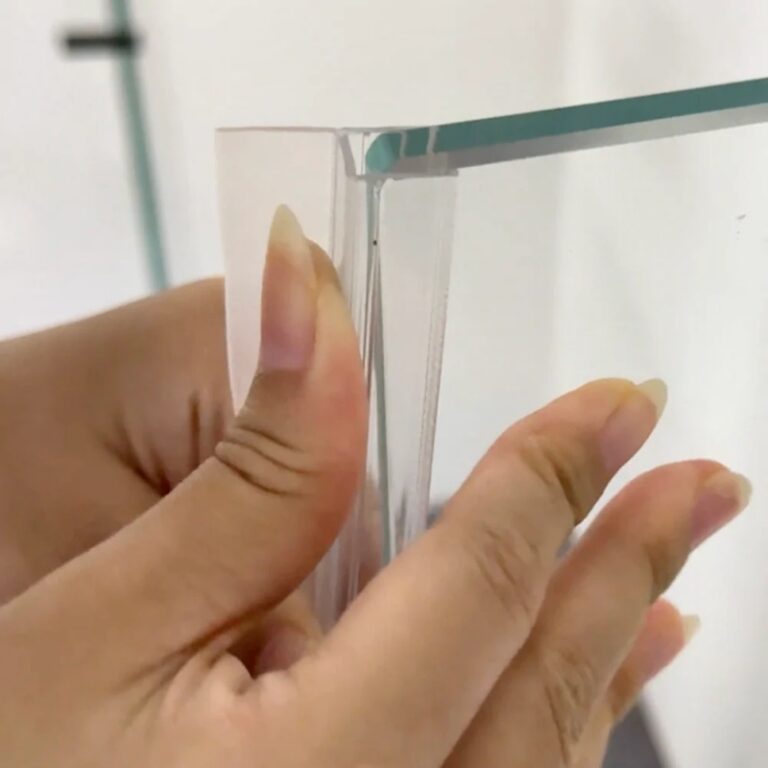

- Module-frame interfaces where glass meets aluminum frames

- Mounting connection points where brackets penetrate seal lines

- Cable entry points where wiring enters junction boxes

Each of these vulnerabilities requires specific solar panel sealing strip solutions tailored to the unique stresses encountered at different locations within the array.

Comprehensive Solutions for Solar Panel Gap Sealing

Waterproof Solar Panel Gap Sealing Strip Technologies

Modern waterproof solar panel gap sealing strip products employ advanced engineering to address the unique challenges of photovoltaic installations:

Closed-cell sponge rubber seals offer exceptional compression recovery and moisture resistance, ideal for uneven surfaces between panels. These solar panel gap sealing strips maintain their sealing properties through years of thermal cycling and compression set resistance.

Dense extruded profiles provide maximum environmental protection for critical interfaces where structural integrity matters most. When considering how do you seal the gap between solar panels in high-wind or seismic zones, these robust profiles offer both sealing performance and mechanical support.

Dual-durometer designs combine soft sealing surfaces with rigid structural cores, addressing both compression sealing needs and installation stability requirements. This approach represents the best sealing strip for gaps in photovoltaic solar panels when both environmental protection and long-term dimensional stability are priorities.

Specialized Profiles for Photovoltaic Applications

Beyond standard strips, specialized profiles enhance solar sealing:

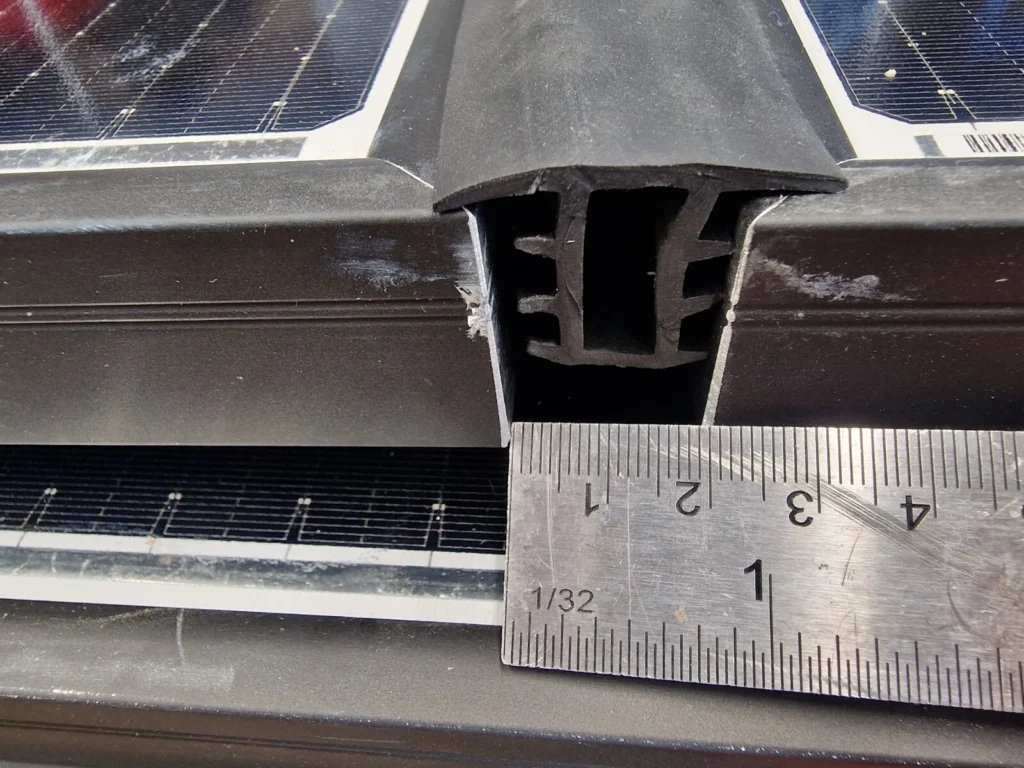

Solar panel T-gasket systems create continuous seals along panel edges while allowing for thermal expansion and contraction. Their unique shape accommodates manufacturing tolerances while providing consistent compression across the sealing surface.

Channel-mounted seals integrate with mounting system profiles, streamlining installation while ensuring proper alignment and compression. These systems address how do you seal the gap between solar panels with factory-like precision in field installations.

Corner and transition pieces complete sealing systems at termination points and direction changes, eliminating the weak points where most generic sealing solutions fail.

Material Comparison: EPDM, Silicone, and Advanced Polymers

EPDM Gasket for Solar Panels: The Industry Standard

EPDM (Ethylene Propylene Diene Monomer) rubber has become the benchmark for solar panel rubber seal strip applications due to its exceptional balance of properties:

Weather Resistance: EPDM maintains flexibility and sealing force from -40°C to +130°C, withstanding decades of UV exposure without significant degradation. An EPDM gasket for solar panels typically offers 20-30 years of reliable service in direct sunlight.

Moisture Performance: With extremely low water absorption rates (<1%), EPDM seals effectively resist swelling and compression set in humid environments, making it ideal for waterproof solar panel gap sealing strip applications.

Cost Efficiency: EPDM provides the most favorable lifecycle cost of major sealing materials, offering premium performance at moderate material costs. For most installations, EPDM gasket for solar panels represents the optimal balance between performance and investment.

Silicone Rubber Sealing Strips: Premium Performance

Silicone rubber offers distinct advantages for specialized applications:

Temperature Range: Superior performance in extreme temperatures (-60°C to +230°C) makes silicone ideal for concentrated photovoltaic or desert installations.

Chemical Resistance: Excellent resistance to ozone and oxidation extends service life in polluted industrial environments.

Electrical Properties: As a natural insulator, silicone adds an extra layer of electrical safety at connection points.

Considerations: Higher material costs and reduced tear strength make silicone most appropriate for specific applications rather than general sealing between solar panels.

Advanced Polymer Blends: Next-Generation Solutions

Innovative material science has produced specialized compounds addressing specific photovoltaic challenges:

TPE/TPV Thermoplastics: These recyclable materials offer design flexibility and color stability with good environmental resistance, though with more limited temperature ranges than EPDM.

Fluoroelastomers: Exceptional chemical and temperature resistance suits them for harsh industrial environments, though at premium pricing.

Foam-Tape Hybrids: Combining adhesive backing with foam sealing cores, these products simplify installation but require careful surface preparation for long-term performance.

Technical Selection Criteria for Optimal Performance

Compression Set Resistance: The Key to Longevity

When evaluating rubber sealing strips for photovoltaic modules, compression set resistance—the material’s ability to return to its original thickness after compression—separates premium products from inadequate solutions. Quality solar panel sealing strips should maintain at least 80% recovery after 10,000 hours at 70°C, ensuring continuous sealing force through decades of thermal cycling.

UV and Ozone Resistance Specifications

Photovoltaic seals require exceptional UV stability. Premium EPDM gasket for solar panels should meet or exceed:

- ASTM D1149 ozone resistance: No cracking after 168 hours at 40°C and 50 pphm ozone concentration

- ASTM D750 UV resistance: Maximum 25% change in tensile strength after 1000 hours of UV exposure

- Color stability: Minimum ΔE of 5 after 5000 hours of accelerated weathering

Water Immersion and Humidity Performance

Given their constant exposure to weather, waterproof solar panel gap sealing strip products must demonstrate:

- Less than 5% volume change after 7 days immersion at 70°C (per ASTM D471)

- Maintaining at least 75% of original tensile strength after humidity aging

- No surface tackiness or bloom after prolonged moisture exposure

Thermal Cycling Compatibility

Solar arrays experience daily temperature fluctuations exceeding 50°C. The best sealing strip for gaps in photovoltaic solar panels must accommodate:

- Coefficient of thermal expansion matching adjacent materials (aluminum and glass)

- Retention of adhesion and sealing force through 200+ thermal cycles

- No cracking or hardening at low temperatures during winter operation

Installation Best Practices for Maximum Effectiveness

Surface Preparation: The Foundation of Reliable Sealing

Proper installation begins long before applying solar panel rubber seal strip:

- Surface Cleaning: Remove all contaminants using isopropyl alcohol or specialized cleaners

- Primer Application: Use manufacturer-recommended primers on difficult substrates

- Temperature Considerations: Install seals between 15°C and 35°C for optimal adhesion

- Humidity Control: Apply seals only when relative humidity is below 85%

Application Techniques for Different Seal Types

Self-adhesive seals require firm, continuous pressure along the entire length using J-rollers to eliminate air pockets and ensure complete substrate contact.

Mechanically fastened seals need consistent torque application on fasteners to achieve uniform compression without distortion or localized over-compression.

Inter-panel gap sealing between adjacent modules requires special attention to corner details and transition points where stress concentrates.

Quality Verification and Inspection Protocols

Post-installation verification ensures sealing between solar panels meets design specifications:

- Visual Inspection: Check for consistent compression, proper alignment, and absence of gaps

- Compression Measurement: Verify seal compression falls within manufacturer’s recommended range (typically 25-40%)

- Water Testing: Perform controlled water exposure tests on sample sections before full installation

- Documentation: Record batch numbers, installation conditions, and inspection results for warranty validation

Regional Considerations for International Buyers

Tropical and High Humidity Environments

In Southeast Asia, South America, and coastal regions, waterproof solar panel gap sealing strip products face exceptional challenges:

Material Selection: EPDM with enhanced fungicide additives prevents biological growth in constantly humid conditions. Solar panel gap sealing strips in these regions require minimum 95% closed-cell content to prevent moisture wicking.

Design Considerations: Wider sealing surfaces accommodate greater thermal movement in high-temperature, high-humidity cycles. Drainage channels integrated into solar panel T-gasket designs prevent water accumulation at critical interfaces.

Installation Timing: Schedule installations during dry seasons when possible, and use temporary protective covers during rainy periods until sealants fully cure.

Desert and Extreme Temperature Regions

Middle Eastern, African, and desert installations demand exceptional temperature performance:

Material Specifications: EPDM gasket for solar panels in desert applications should include additional UV stabilizers and heat-resistant compounds. Silicone alternatives may be justified for specific high-temperature applications exceeding 100°C surface temperatures.

Expansion Accommodation: Wider gaps between panels (minimum 10mm) accommodate greater thermal expansion, requiring proportionally larger solar panel sealing strips.

Dust and Sand Protection: Specialized felt or brush seals combined with rubber primary seals create multi-stage filtration keeping abrasive particles from critical interfaces.

Cold Climate and High Altitude Applications

Northern European, Canadian, and mountainous installations present unique challenges:

Low-Temperature Flexibility: Rubber sealing strips for photovoltaic modules must remain flexible at -40°C without cracking or hardening. Specialty low-temperature EPDM compounds maintain elasticity in extreme cold.

Snow Load Considerations: Seals must accommodate frame deflection under snow loads without permanent deformation. High-recovery formulations with memory characteristics are essential.

Freeze-Thaw Cycling: Materials must withstand repeated freeze-thaw cycles without micro-crack development that compromises long-term sealing integrity.

Cost-Benefit Analysis: Balancing Performance and Investment

Initial Cost vs. Lifetime Value Calculation

When selecting solar panel rubber seal strip products, consider the total cost of ownership:

Premium EPDM seals typically cost 20-40% more than basic alternatives but deliver 300-500% longer service life in photovoltaic applications. The best sealing strip for gaps in photovoltaic solar panels isn’t the cheapest initially, but rather the most cost-effective over a 25-year system lifespan.

Performance Metrics Correlation: Each 10% increase in compression set resistance typically correlates with 3-5 years of additional service life. Similarly, premium UV stabilization adds 5-8 years to effective sealing life in direct sunlight applications.

Warranty and Performance Guarantee Evaluation

Reputable manufacturers of EPDM gasket for solar panels offer material warranties ranging from 10-25 years. Key warranty considerations include:

Coverage Specifics: Comprehensive warranties cover material degradation, compression set failure, and environmental damage—not just manufacturing defects.

Prerequisites: Proper installation, compatible surfaces, and environmental limitations affect warranty validity. Documentation of installation conditions is essential for claims.

Global Support: For international buyers, manufacturers with worldwide distribution networks provide better warranty support than regional suppliers.

Maintenance and Replacement Cost Projections

Quality sealing between solar panels reduces long-term maintenance costs:

Preventive Maintenance: Properly installed premium seals require only annual visual inspection and occasional cleaning, with no scheduled replacement for 15-20 years.

Corrective Costs: Seal failure typically requires complete panel removal for replacement, costing 3-5 times the original installation labor. Premium materials preventing this scenario offer substantial savings.

System Downtime: Energy production losses during seal replacement further justify investment in premium waterproof solar panel gap sealing strip products from the initial installation.

Future Trends and Innovation in Photovoltaic Sealing

Smart Sealing Technologies

Emerging technologies are transforming solar panel gap sealing strips from passive components to active system elements:

Integrated Monitoring: Micro-encapsulated color-changing additives visually indicate seal degradation before failure occurs, enabling proactive maintenance.

Conductive Rubber Compounds: New formulations can monitor continuity of the moisture barrier, integrating with building management systems to alert operators to developing issues.

Self-Healing Materials: Experimental polymers with micro-encapsulated healing agents automatically repair minor damage from hail or debris impact.

Sustainability and Circular Economy Developments

Environmental considerations are driving material innovation:

Bio-based EPDM: Research into renewable-source ethylene and propylene may yield EPDM gasket for solar panels with identical performance and reduced carbon footprint.

Recyclable Thermoplastic Rubbers: New TPE formulations approach EPDM’s weather resistance while offering complete recyclability at end-of-life.

Reduced Installation Waste: Precision-cut kits and reel-less packaging minimize installation waste for solar panel sealing strip products.

Making Your Optimal Selection

Decision Framework for Different Project Types

Residential installations typically benefit from standardized solar panel T-gasket systems offering balanced performance and straightforward installation. Commercial projects often require custom-engineered rubber sealing strips for photovoltaic modules addressing specific structural and environmental challenges. Utility-scale installations demand the best sealing strip for gaps in photovoltaic solar panels with proven 25-year field performance data and comprehensive warranty coverage.

Supplier Qualification Checklist

When sourcing waterproof solar panel gap sealing strip products, verify suppliers offer:

- ISO 9001 quality certification specifically for rubber extrusion

- Third-party tested material properties with published data sheets

- Photovoltaic industry experience with verifiable project references

- Technical support for design and installation challenges

- Global supply chain reliability and local inventory where needed

Sample Testing Protocol

Before committing to large purchases, implement a validation process:

- Accelerated Aging: Subject samples to 1000 hours of UV and thermal cycling

- Compression Testing: Verify recovery after 30% compression at elevated temperature

- Compatibility Testing: Confirm no adverse reactions with specific panel frames and mounting systems

- Installation Simulation: Test application on sample sections mimicking field conditions

Conclusion: Sealing Your Solar Investment

The critical importance of sealing between solar panels cannot be overstated in photovoltaic system design and installation. What begins as a seemingly minor component—the solar panel rubber seal strip—ultimately determines the long-term reliability, efficiency, and safety of entire solar arrays across diverse global environments.

From basic solar panel gap sealing strips to advanced EPDM gasket for solar panels with specialized formulations, today’s market offers solutions precisely tailored to every application challenge. By understanding material properties, installation requirements, and lifecycle value—rather than just initial cost—buyers can select the best sealing strip for gaps in photovoltaic solar panels that will protect their energy investments for decades.

The question of how do you seal the gap between solar panels ultimately has multiple answers, each appropriate for different environments, system designs, and performance requirements. Through careful evaluation of the factors outlined in this guide—from material science to regional considerations—you can implement waterproof solar panel gap sealing strip solutions that deliver optimal performance, maximum durability, and the highest return on your photovoltaic investment.

As solar technology continues advancing, so too will rubber sealing strips for photovoltaic modules, with smarter materials, more sustainable formulations, and enhanced functionality. By staying informed about these developments while applying proven selection criteria today, you ensure your sealing solutions meet current needs while remaining compatible with tomorrow’s photovoltaic innovations.