Customized Rubber Seal Strips: Tailored Solutions for Every Industry Need

Rubber seal strips are the unsung heroes of modern engineering, providing critical protection against environmental elements while ensuring energy efficiency and operational safety. At their core, these versatile components serve as barriers against water, dust, air, noise, and temperature fluctuations. However, the true power of rubber seal strips products lies in their customization potential—allowing businesses across sectors to solve specific challenges with precision-engineered solutions.

Understanding the Diverse Needs of International Buyers

International procurement of customized rubber seal strips isn’t about finding a one-size-fits-all product. It’s about identifying specific pain points and engineering solutions that address them directly. Here’s how we approach design for different buyer segments:

1. Construction and Architectural Sector: Door Rubber Seal Strips & Window Rubber Seal Strips

Building professionals seek solutions that combine energy efficiency with durability.

Design Focus:

-

EPDM rubber seal strips dominate this sector due to exceptional weather resistance (withstanding temperatures from -40°C to +120°C)

-

Compression set optimization for long-term performance despite door/window movement

-

UV-stabilized formulations for exterior applications

-

Color matching capabilities for aesthetic integration

-

Adhesive backing options for simplified installation on various surfaces

Problem Solved: Reducing energy loss by up to 30% while preventing water intrusion and noise pollution.

2. Automotive Industry: Automotive Rubber Seal Strips & Car Door Rubber Seal Strips

Automotive manufacturers and aftermarket suppliers demand precision, durability, and noise reduction.

Design Focus:

-

Hollow bulb, dense, or sponge profiles tailored to specific sealing zones

-

Low-friction coatings for smooth window and door operation

-

Chemical resistance against automotive fluids and road salts

-

Temperature resilience for engine compartments (-40°C to +150°C)

-

Silicone rubber seal strips for high-temperature applications near engines

Problem Solved: Ensuring passenger compartment comfort, reducing road noise by 5-10 dB, and extending vehicle lifespan by preventing corrosion.

3. Industrial Applications: Industrial Rubber Seal Strips

Factory and machinery operators require seals that withstand harsh conditions and specialized environments.

Design Focus:

-

Chemical-resistant formulations (NBR, Viton) for specific industrial fluids

-

Fire-retardant options for safety-critical applications

-

Conductive rubber for EMI/RFI shielding in electronic enclosures

-

High-compression resistance for heavy machinery doors

-

Food-grade silicone for pharmaceutical and food processing

Problem Solved: Preventing contamination, ensuring worker safety, reducing equipment downtime, and maintaining cleanroom classifications.

4. Niche Applications: Small Rubber Seal Strips & Specialty Seals

Electronics manufacturers, appliance makers, and specialized equipment producers need miniature precision sealing.

Design Focus:

-

Micro-extrusion capabilities for seals as small as 1mm cross-section

-

Medical-grade materials for healthcare equipment

-

Static dissipative options for sensitive electronics

-

Transparent silicone for aesthetic applications

-

Precision die-cutting for complex geometries

Problem Solved: Enabling miniaturization of products while maintaining environmental protection and meeting regulatory requirements.

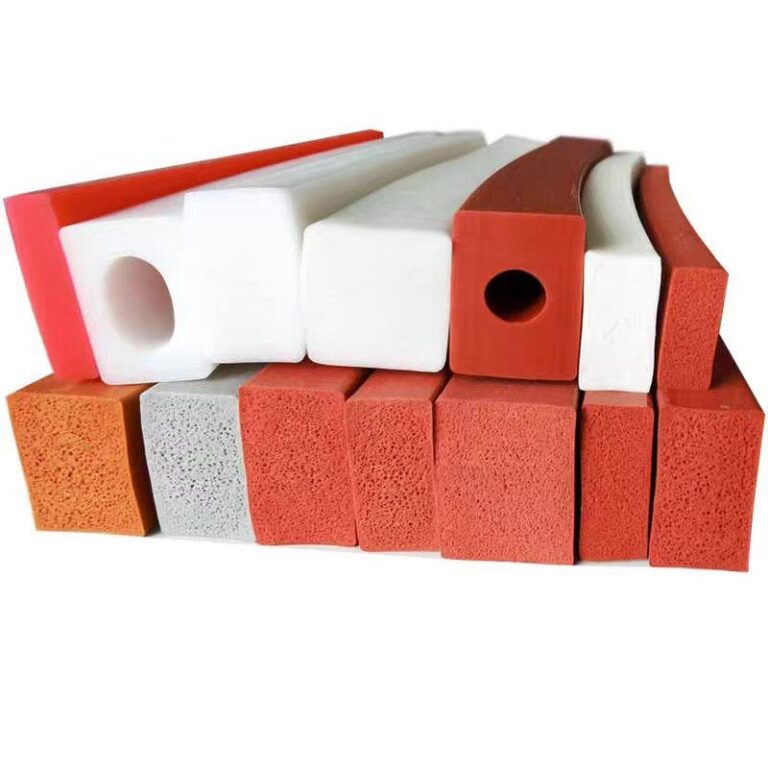

Material Selection: The Foundation of Effective Customization

EPDM Rubber Seal Strips: The all-rounder for outdoor applications, offering excellent ozone, weather, and temperature resistance. Ideal for rubber weather seal strips and rubber water seal strips.

Silicone Rubber Seal Strips: Superior for extreme temperatures (-60°C to +230°C), FDA compliance, and chemical resistance. Perfect for medical, food, and high-heat automotive applications.

Neoprene: Excellent for oil and moderate chemical resistance with good compression set properties.

Nitrile (NBR): Superior resistance to oils, fuels, and chemicals for industrial applications.

Foam Rubber Strips: Lightweight, compressible options for irregular surfaces and sound damping.

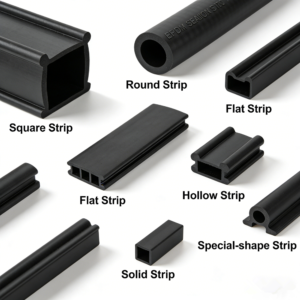

The Customization Process: From Problem to Solution

-

Problem Identification: Understanding the exact environmental challenges (water ingress, dust penetration, noise transfer, thermal transfer)

-

Profile Design: Engineering the cross-sectional geometry for optimal compression and sealing performance

-

Material Specification: Selecting base polymers and additives for environmental resistance

-

Attachment Method: Choosing among adhesive backing, mechanical retention, or press-fit designs

-

Prototyping and Testing: Validating performance under simulated conditions

-

Production and Quality Assurance: Ensuring batch-to-batch consistency

Global Procurement Considerations

International buyers should evaluate suppliers based on:

-

ISO 9001 certification for quality management

-

Material traceability and certification

-

Testing capabilities (compression set, weather aging, chemical resistance)

-

Minimum order quantity flexibility

-

Lead time reliability

-

Packaging optimized for international shipping

Future Trends in Rubber Seal Technology

The next generation of rubber seal strips products will incorporate:

-

Smart seals with embedded sensors for predictive maintenance

-

Sustainable materials with recycled content and improved recyclability

-

Enhanced fire safety properties for building applications

-

Improved adhesion technologies for challenging substrates

Conclusion: Beyond the Strip

Customized rubber seal strips represent far more than simple rubber profiles—they are engineered solutions to specific environmental challenges. Whether it’s car rubber seal strips that make vehicles quieter and more efficient, industrial rubber seal strips that protect expensive machinery, or window rubber seal strips that reduce energy costs, the right customized solution delivers measurable ROI through improved performance, reduced maintenance, and extended equipment life.

For international buyers, the key lies in partnering with manufacturers who invest in understanding application specifics rather than simply selling standard products. The optimal rubber door seal strips for a Scandinavian apartment building differ significantly from those needed for a Middle Eastern commercial facility—not just in material formulation, but in compression characteristics, joint design, and installation methodology.

In today’s competitive global market, customized sealing solutions provide the differentiation that turns ordinary products into exceptional ones, solving real-world problems through thoughtful material science and precision engineering.