Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

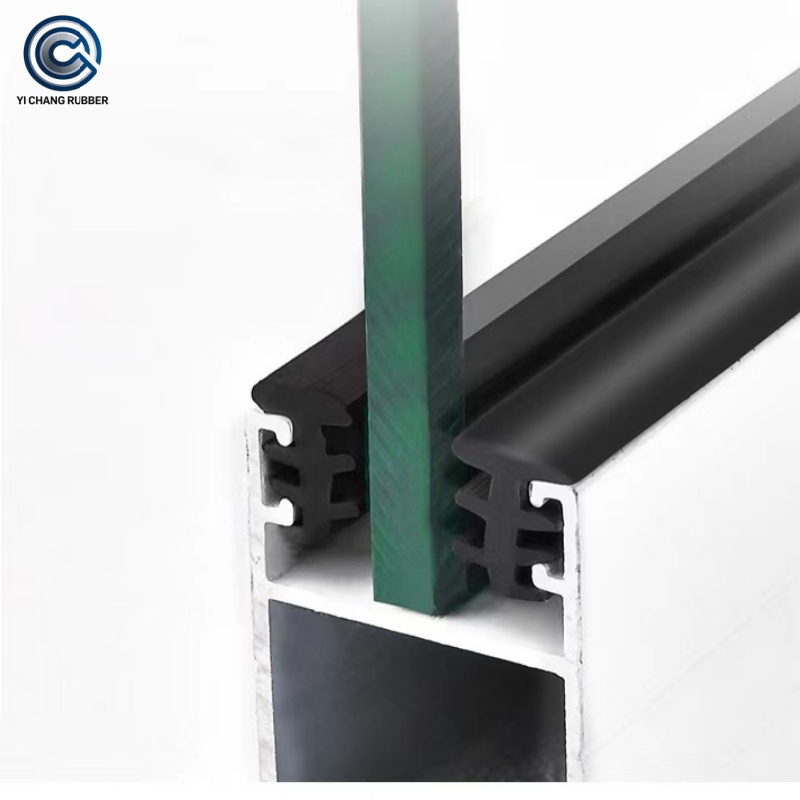

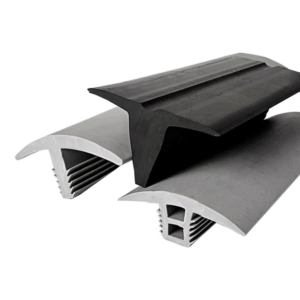

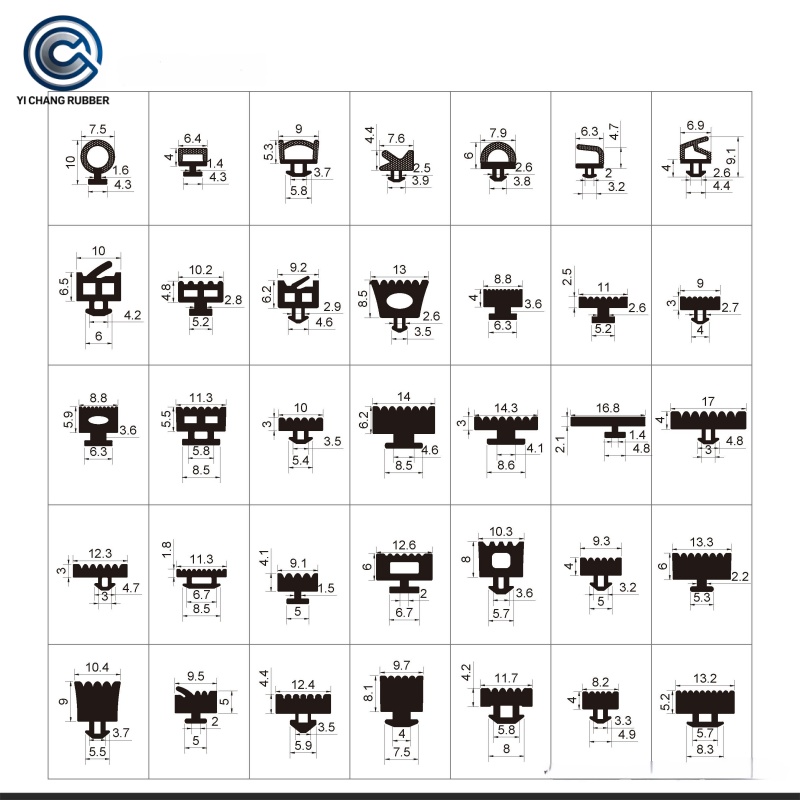

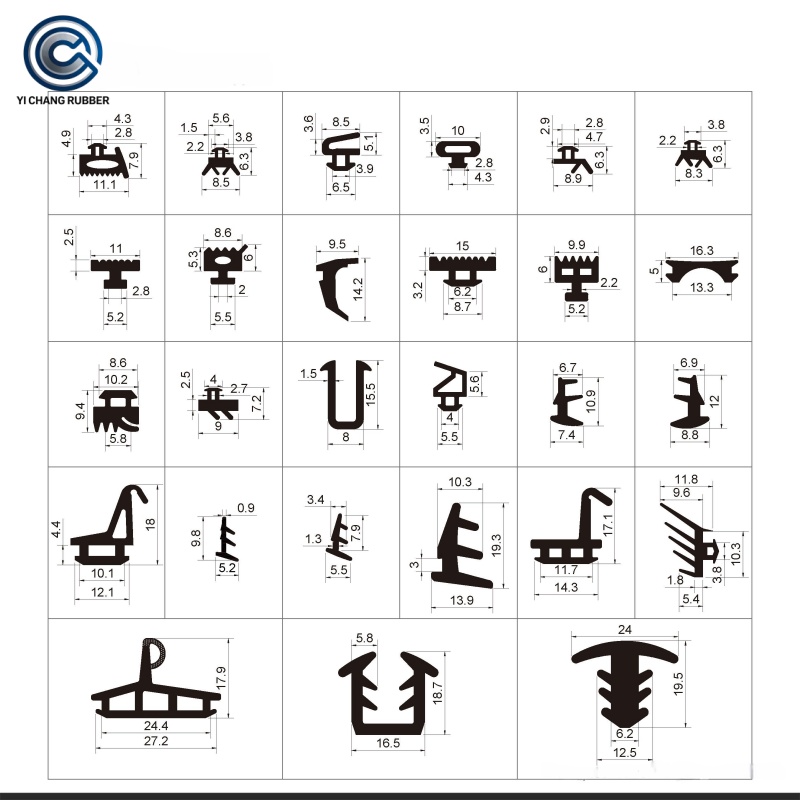

EPDM Special-shaped Strip

DIY EPDM Weather Sealing Kit – Easy Cut & Install All Tools Included Custom EPDM seals

-

Precision Extruded: Tailored to your exact dimensional blueprints and specifications.

-

Material Versatility: Choose from multiple EPDM grades (standard, dense, sponge).

-

Any Profile Possible: Manufacture simple to highly complex cross-sectional shapes.

-

Color Matching: Available in standard black or custom-matched colors per RAL/Pantone.

-

Bulk & Prototype Orders: Serve both low-volume prototyping and high-volume production.

EPDM closed-cell foam sealing tape provides superior weatherproofing and insulation for construction, automotive, and industrial applications. Made from durable synthetic rubber, it excels in resisting UV rays, extreme temperatures (-40°C to +120°C), ozone, and water absorption. Its excellent compression recovery ensures a long-lasting, airtight, and watertight seal around windows, doors, HVAC ducts, and panels. Available with strong pressure-sensitive adhesive backing for easy installation, this flexible strip reduces energy costs by blocking drafts, moisture, and noise. It is the preferred choice for reliable, durable sealing solutions in harsh outdoor environments.

Available Forms

Self-adhesive strips (most common)

Plain foam strips without adhesive

Various densities and compression ratings

Different cross-sections: rectangular, round, D-shape, P-shape

Multiple colors (black most common, also available in gray, white)

Advantages Over Other Materials

Better weather resistance than natural rubber or PVC

More durable than open-cell foams (which can absorb water)

More flexible and compressible than solid EPDM rubber

Cost-effective for many applications compared to specialized seals

Installation Tips

Clean and dry surfaces thoroughly

For adhesive strips: peel backing and apply with firm pressure

Avoid stretching during installation

Ensure proper compression (typically 25-50% compression recommended)

EPDM foam sealing strips offer a practical balance of performance, durability, and cost for applications requiring reliable sealing against environmental elements.

Superior Weather Resistance: Excellent resistance to UV radiation, ozone, and extreme temperatures (typically from -40°C to +120°C), preventing cracking or degradation.

Waterproof & Moisture-Proof: Closed-cell foam structure ensures minimal water absorption, preventing rot, mold, and loss of insulating properties.

Excellent Compression Set Resistance: Maintains its sealing force over time by returning to its original shape after prolonged compression, ensuring a durable seal.

High Elasticity & Flexibility: Conforms easily to uneven surfaces and gaps, providing an effective seal against air, water, and dust.

Thermal & Acoustic Insulation: Enhances energy efficiency by reducing heat transfer and helps dampen sound transmission.

Chemical & Environmental Resistance: Resists many common chemicals, polar solvents, and weathering elements, making it suitable for harsh environments.

Adhesive Options: Often available with a high-tack pressure-sensitive acrylic adhesive (PSA) backing for quick, strong, and permanent installation on clean surfaces.

Durability & Long Service Life: Offers a significantly longer lifespan than open-cell foams or PVC in outdoor applications due to its stable polymer structure.

What is the typical lead time for custom EPDM foam strips?

Can EPDM foam strips be painted or color-matched?

Is it truly waterproof, and what is its closed-cell content?

What is the compression set, and how long will the seal last?

What adhesive backing is recommended for our substrate (metal, plastic, concrete)?

Construction & Building

Windows & Doors: Sealing between frames and masonry, perimeter weatherstripping, and glazing seals.

Curtain Wall & Panel Systems: Sealing joints between prefabricated panels and metal/glass facades.

Roofing & Cladding: Sealing around roof penetrations, skylights, and at expansion joints.

Expansion Joint Covers: Filling and sealing movement joints in concrete and metal structures.

HVAC & Mechanical

Air Duct Sealing: Sealing joints and connections in HVAC ductwork to prevent air leakage.

Equipment Enclosures: Gasketing for access panels, outdoor units, and air handling housings.

Vibration Damping: Isolating vibrations from fans, compressors, and machinery.

Automotive, Marine & Transportation

Vehicle Seals: Door, trunk, and hood perimeter seals; window channel seals.

Cabinet & Access Panel Seals: Sealing compartments in RVs, boats, and commercial vehicles.

Engine Bay & Component Gaskets: Sealing non-high-temperature covers and housings.

General Industrial & Manufacturing

Electrical Enclosures: Creating dust-proof and water-resistant seals (IP ratings) for control boxes and outdoor cabinets.

Machine Guards & Safety Covers: Sealing gaps to contain debris and reduce noise.

Conveyor System Sealing: Dust and splash guards in manufacturing facilities.

Key Application Advantages:

In these uses, the strip is valued for its durability against environmental stress, reliable compression recovery for long-term performance, and ease of installation with adhesive backing.