Creat a one-stop cooperative procument service for rubber seal strips

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

Nitrile Butadiene Rubber Products NBR

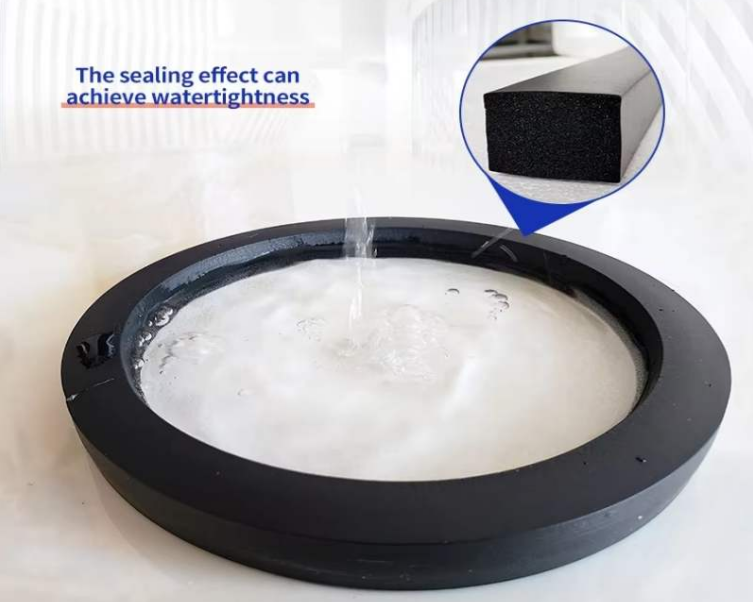

NBR Nitrile Rubber Foam Insulation & Packaging Solution for Construction

- Excellent resistance to oils, fuels, fats, diluted acids and alcohols.

- Strong abrasion, tear and impact resistance

- High elasticity and long-term durability

- Non-toxic safety certification

Nitrile Butadiene Rubber (NBR), commonly known as Buna-N, is a synthetic elastomer copolymer made via emulsion polymerization of acrylonitrile (ACN) and butadiene. Renowned for top-tier oil resistance among synthetic rubbers, NBR is a flexible material widely applied in automotive, aerospace, petroleum, and general industrial fields globally, serving as the preferred choice for oil-contacting parts.

This core advantage stems from polar cyano (-CN) groups in its molecular chain, granting strong resistance to mineral oils, fuels, greases, and non-polar solvents. It offers reliable heat resistance (long-term -40℃ to 120℃, short-term up to 150℃ in oil), plus excellent abrasion resistance, airtightness, water resistance, adhesion, and easy mass-processability—solidifying its status as an industrial staple.

NBR is classified by acrylonitrile (ACN) content into five grades: ultra-high (≥43% ACN), high (36%-42% ACN), medium-high (31%-35% ACN), medium (25%-30% ACN), and low (≤24% ACN). Higher ACN enhances oil resistance and airtightness but reduces low-temperature flexibility, enabling tailored NBR solutions for diverse needs.

Key applications include automotive (fuel hoses, oil seals, gaskets), aerospace (fuel system seals), petroleum (drilling hoses, tank liners), printing (ink rollers), and protective gear (oil-resistant gloves). Modified variants like HNBR and XNBR extend its utility to high-temperature and high-adhesion scenarios.

As a cost-effective oil-resistant synthetic rubber, NBR balances performance and affordability. We supply premium NBR with customized ACN content, ideal for harsh industrial environments. Contact us for tailored solutions to upgrade your products.

Can you customize NBR products according to specific procurement requirements?

What certifications do your NBR products have for global procurement?

What is the lead time for bulk NBR procurement?

How to select the right ACN grade of NBR for different applications?

Do you provide pre-shipment quality inspection for NBR orders?