Silicone Foam Sealing Strip: Supplier’s Guide for OEMs & Industrial Buyers

A silicone foam sealing strip is a soft, compressible, sponge-like sealing material made from silicone rubber. It’s formed by creating a uniform cellular (foam) structure within the silicone, resulting in a lightweight, flexible strip with excellent sealing and gasketing properties. It often has a self-adhesive backing for easy installation.

Key Characteristics and Composition

-

Material: Made from silicone rubber, a synthetic elastomer known for its stability across extreme temperatures and environmental resistance.

-

Structure: The “foam” refers to its closed-cell structure. This means the tiny bubbles (cells) within the material are not interconnected. This is crucial for its performance:

-

Prevents water and air penetration through the material itself.

-

Low compression set (it bounces back after being squished).

-

Excellent sealing against moisture, dust, wind, and light.

-

Primary Properties and Advantages

-

Extreme Temperature Resistance: Performs reliably from -60°C to +200°C (and up to 300°C for short periods). It won’t melt, become brittle, or significantly degrade.

-

Excellent Weather & UV Resistance: Highly resistant to ozone, sunlight (UV), rain, snow, and oxidation. Ideal for outdoor and automotive applications.

-

Chemical Resistance: Resists many chemicals, oils, solvents, and salts.

-

Fire Retardancy: Many grades are self-extinguishing and meet industry fire safety standards (e.g., UL 94).

-

Flexibility & Compression Recovery: Maintains its elasticity and shape over time, providing a long-lasting seal even with repeated compression cycles.

-

Electrically Insulative: A good electrical insulator, making it suitable for electronics and electrical enclosures.

-

Non-Toxic & Odorless: Often compliant with FDA and RoHS regulations, safe for use in food-grade and medical environments.

Common Applications

Silicone foam strips are used wherever a reliable, durable seal is needed in challenging conditions.

-

Electronics & Electrical Enclosures: Sealing control panels, junction boxes, LED lights, and outdoor telecom cabinets against dust and water (often to IP ratings).

-

Automotive: Sealing engine compartments, LED headlights/taillights, battery covers, and HVAC systems against heat, fumes, and noise.

-

Appliances: Gaskets for ovens, heaters, dishwashers, and other high-temperature appliances.

-

HVAC & Ducting: Sealing connections in high-temperature air handling systems.

-

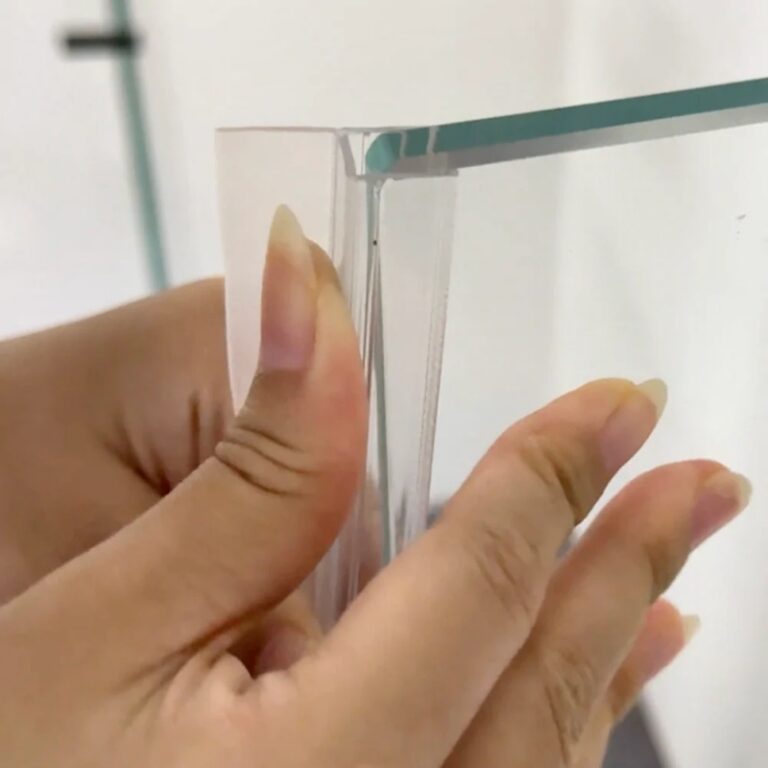

Construction & Glazing: Weatherproofing seals for windows, doors, and curtain walls in demanding architectural projects.

-

Aerospace & Transportation: Used in cabins, doors, and panels where fire safety and temperature extremes are critical.

-

Medical Equipment: Sealing for sterilizable equipment and imaging devices due to its cleanliness and stability.

Comparison with Common Alternatives

| Feature | Silicone Foam Strip | EPDM Foam Strip | Polyurethane (PU) Foam Strip | Solid Rubber Gasket |

|---|---|---|---|---|

| Temp Range | Excellent (-60°C to +200°C+) | Good (-40°C to +130°C) | Moderate | Varies by material |

| Weather/UV | Excellent | Excellent | Poor, degrades in sunlight | Good (if EPDM) |

| Compression Set | Very Low (Recovers well) | Low | Can be high (flattens over time) | Low |

| Cost | Higher | Lower | Lower | Varies |

| Best For | Extreme temps, critical seals | General outdoor weather sealing | Indoor, low-cost cushioning | High-pressure, fluid sealing |

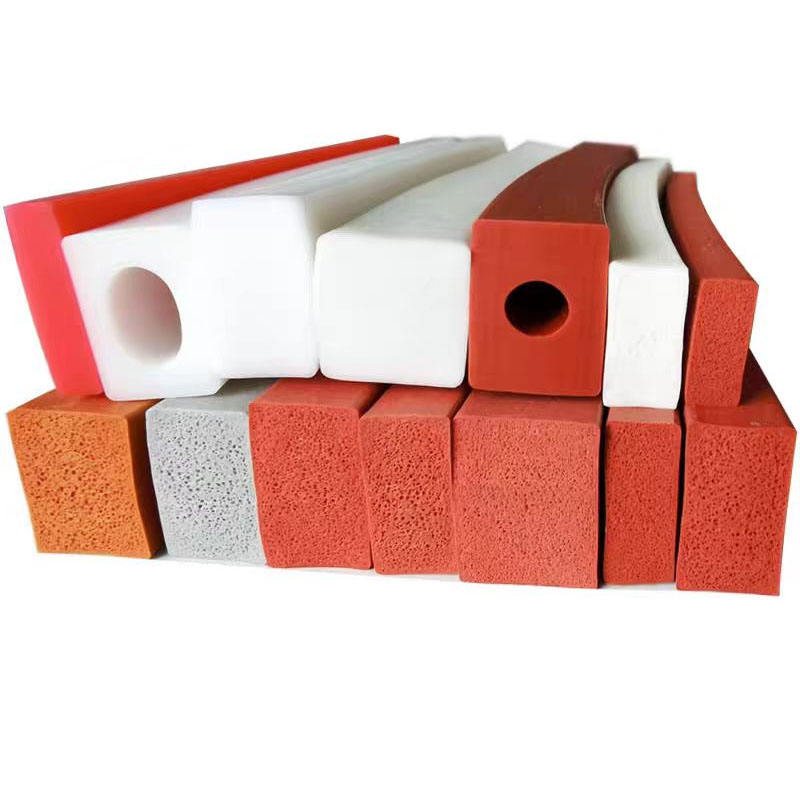

Typical Forms and Installation

-

Shapes: Most commonly supplied as strips or rolls with rectangular, D-shaped, or round cross-sections.

-

Self-Adhesive Backing: Most strips come with a high-tack acrylic or silicone adhesive on one side, protected by a release liner. This allows for quick, tool-free installation.

-

Customization: Can be die-cut into complex gaskets and shapes for specific applications.

Summary

A silicone foam sealing strip is a premium, high-performance sealing solution designed for the most demanding environments. Its combination of extreme temperature tolerance, superb environmental resistance, and long-term elasticity makes it the material of choice when reliability is paramount and conditions are harsh. While more expensive than some alternatives, its durability and performance often make it the most cost-effective choice over the long term.