Creat a one-stop cooperative procument service for rubber seal strips

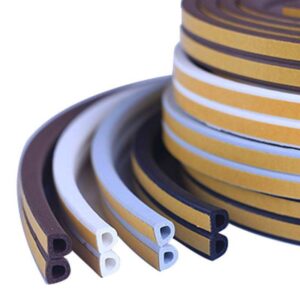

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

Rubber Seal Strips for Auto & Vehicle Industry – Complete Material Guide

Rubber seal strips are indispensable components in the automotive and vehicle industry, serving as protective barriers against moisture, dust, noise, vibration, and temperature extremes. These seemingly simple components perform critical functions—from ensuring passenger comfort and cabin quietness to protecting sensitive electronic components and maintaining structural integrity. Selecting the right rubber seal material directly impacts vehicle performance, durability, safety, and cost-effectiveness.

For automotive buyers and procurement specialists, understanding the material differences, application-specific requirements, and cost-performance tradeoffs is essential for making informed purchasing decisions. This comprehensive guide analyzes the most common rubber seal materials used in automotive applications, their distinct properties, and how to select the optimal material for your specific needs.

Why Material Selection Matters: Performance and Longevity Factors

Choosing inappropriate rubber seal material leads to premature failure, resulting in:

Water leaks and moisture damage to interior components

Increased wind noise and reduced acoustic comfort

Energy loss through poor thermal insulation

Safety concerns due to compromised door or window seals

Frequent replacements and higher total cost of ownership

The right material selection ensures:

Extended product lifespan matching vehicle durability expectations

Consistent performance across temperature extremes (-40°C to 120°C+)

Resistance to automotive fluids (oils, fuels, cleaning agents)

Optimal compression set recovery for lasting sealing force

Cost-effectiveness through appropriate material specification

Comprehensive Analysis of Automotive Rubber Seal Materials

1. EPDM (Ethylene Propylene Diene Monomer)

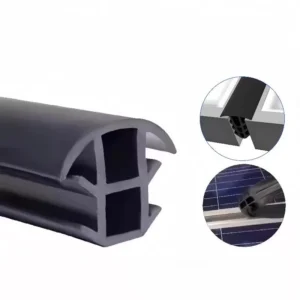

Primary Applications: Door seals, window seals, trunk seals, sunroof seals, hood seals

Key Properties:

Exceptional weather and ozone resistance

Excellent temperature tolerance (-50°C to 150°C)

Good compression set resistance

Superior UV and oxidation resistance

Good water and steam resistance

Performance Advantages:

EPDM has become the industry standard for exterior automotive seals due to its outstanding weathering capabilities. It maintains flexibility in extreme cold while resisting degradation from heat and ozone exposure. EPDM formulations with carbon black provide excellent UV protection, crucial for components exposed to direct sunlight.

Cost Considerations:

Moderate material cost with excellent lifespan makes EPDM highly cost-effective for exterior applications. Standard-grade EPDM offers the best balance of performance and cost for most exterior sealing applications.

Best For: Buyers needing durable exterior seals with excellent weather resistance at competitive pricing.

2. Silicone Rubber

Primary Applications: Engine compartment seals, high-temperature gaskets, coolant system seals, electrical connector seals

Key Properties:

-

Extreme temperature range (-60°C to 230°C+)

-

Excellent ozone and UV resistance

-

Good compression set at high temperatures

-

Maintains flexibility at low temperatures

-

Inert and suitable for food/medical grade applications

Performance Advantages:

Silicone rubber excels in extreme temperature environments where other elastomers fail. Its stable molecular structure provides consistent performance across the widest temperature range of any automotive rubber. Silicone maintains elasticity better than organic rubbers at both high and low temperature extremes.

Limitations:

Lower tensile strength and tear resistance compared to organic rubbers. Higher permeability to gases. Generally higher cost than organic rubbers.

Best For: High-temperature applications, extreme climate conditions, and specialty applications requiring exceptional temperature performance.

3. Neoprene (Chloroprene Rubber)

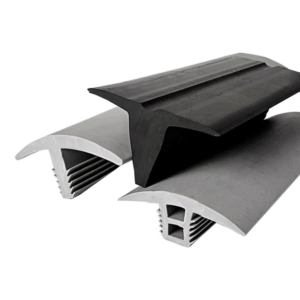

Primary Applications: Fuel system seals, hose connections, vibration mounts, some gasket applications

Key Properties:

-

Good resistance to oils, fuels, and chemicals

-

Moderate weather and ozone resistance

-

Flame retardant properties

-

Good physical strength and toughness

-

Performs well in moderate temperatures (-40°C to 120°C)

Performance Advantages:

Neoprene offers balanced properties with good resistance to petroleum-based products, making it suitable for fuel system applications. It provides better flame resistance than most general-purpose rubbers and maintains decent mechanical properties across a reasonable temperature range.

Best For: Applications requiring oil and fuel resistance at moderate cost, particularly in underhood environments.

4. Natural Rubber

Primary Applications: Suspension bushings, vibration dampeners, some sealing applications requiring high elasticity

Key Properties:

-

Excellent tensile strength and elasticity

-

Good low-temperature flexibility

-

High resilience and rebound

-

Biodegradable and from renewable resources

Limitations:

Poor resistance to oils, fuels, ozone, and UV exposure. Limited high-temperature capability (typically to 70-80°C). Requires stabilization additives for automotive use.

Best For: Applications requiring maximum elasticity and resilience where environmental exposure is minimal.

5. SBR (Styrene Butadiene Rubber)

Primary Applications: Low-cost general-purpose seals, brake system components, some molded parts

Key Properties:

-

Good abrasion resistance

-

Moderate cost

-

Acceptable mechanical properties

-

Can be compounded for improved oil resistance

Limitations:

Poor weather and ozone resistance without additives. Inferior to EPDM for exterior applications. Limited temperature range compared to premium materials.

Best For: Cost-sensitive interior applications or components protected from environmental exposure.

6. Specialty and Hybrid Compounds

TPE/TPV (Thermoplastic Elastomers/Vulcanizates):

Increasingly popular for automotive seals due to recyclability and processing advantages. TPVs (often EPDM/PP blends) offer EPDM-like properties with thermoplastic processing benefits.

Fluoroelastomers (FKM/Viton®):

Exceptional chemical and high-temperature resistance for demanding applications like turbocharger seals, fuel system components, and transmission seals. Higher cost justified for extreme conditions.

Nitrile Rubber (NBR):

Excellent oil and fuel resistance for engine and transmission applications. Often used in combination with other materials for specific property enhancement.

Comparative Analysis: Material Performance Matrix

| Property | EPDM | Silicone | Neoprene | Natural Rubber | SBR | TPV |

|---|---|---|---|---|---|---|

| Temperature Range | -50°C to 150°C | -60°C to 230°C | -40°C to 120°C | -50°C to 80°C | -40°C to 100°C | -60°C to 135°C |

| Weather/Ozone Resistance | Excellent | Excellent | Good | Poor | Poor | Excellent |

| Oil/Fuel Resistance | Poor | Fair | Good | Poor | Fair to Good | Poor to Fair |

| Compression Set Resistance | Very Good | Good at High Temp | Good | Fair | Fair | Good |

| Tear Strength | Good | Fair | Good | Excellent | Good | Good |

| Cost Factor | $$ | $$$ | $$ | $ | $ | $$ |

| Typical Automotive Lifespan | 10-15 years | 15-20 years | 7-10 years | 5-8 years | 5-7 years | 10-15 years |

Selection Guide: Matching Material to Application

Exterior Seals (Doors, Windows, Trunk, Hood)

Recommended Material: EPDM

Why: Superior weather resistance, UV stability, and temperature tolerance make EPDM the ideal choice for exterior seals that must withstand environmental exposure while maintaining sealing force through countless compression cycles.

Alternative: TPV for applications requiring recyclability or specific color matching without painting.

Buyer Consideration: For standard passenger vehicles, EPDM provides optimal cost-performance ratio. For luxury vehicles or extreme climates, consider premium-grade EPDM with enhanced UV stabilizers.

High-Temperature Areas (Engine Bay, Exhaust System)

Recommended Material: Silicone or Fluoroelastomers

Why: Exceptional temperature resistance maintains seal integrity when exposed to engine heat. Silicone offers better low-temperature flexibility, while fluoroelastomers provide superior chemical resistance.

Alternative: Specialty EPDM compounds rated for continuous 150°C+ service.

Buyer Consideration: Assess maximum temperature exposure and whether chemical resistance is required. Silicone typically offers better value unless aggressive fluids are present.

Fluid-Exposed Seals (Fuel Systems, Oil Areas)

Recommended Material: Neoprene, Nitrile, or Fluoroelastomers

Why: These materials maintain physical properties when exposed to petroleum-based fluids that would degrade other elastomers.

Alternative: Hydrogenated Nitrile (HNBR) for enhanced temperature resistance with oil compatibility.

Buyer Consideration: Match material to specific fluid type, concentration, and temperature. Request fluid immersion test data from suppliers.

Vibration Dampening and Mounts

Recommended Material: Natural Rubber or EPDM/NR Blends

Why: High resilience and damping characteristics effectively reduce noise and vibration transmission.

Alternative: Specialty polyurethane compounds for extreme load-bearing applications.

Buyer Consideration: Consider dynamic vs. static applications. Natural rubber excels in dynamic damping but requires protection from environmental exposure.

Cost-Sensitive High-Volume Applications

Recommended Material: SBR or Standard EPDM

Why: Acceptable performance at minimum cost for protected applications or shorter lifespan requirements.

Alternative: Recycled rubber compounds where specifications permit.

Buyer Consideration: Evaluate total cost of ownership including replacement frequency. Lower upfront cost may result in higher long-term expenses.

Advanced Considerations for Automotive Buyers

Material Compounding and Additives

Base polymer selection is only the beginning. Compound formulation significantly affects performance:

-

Fillers: Carbon black improves UV resistance; silica enhances tear strength

-

Plasticizers: Affect low-temperature flexibility and hardness

-

Curing Systems: Influence compression set resistance and heat aging

-

Stabilizers: UV inhibitors, antioxidants, and ozone protectors extend lifespan

Buyer Action: Request complete compound specifications, not just base polymer type.

Hardness (Durometer) Selection

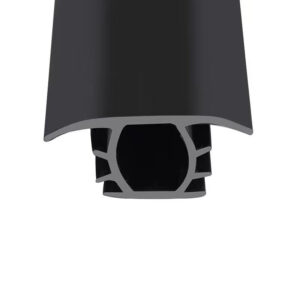

Shore A hardness typically ranges from 40 (soft) to 80 (hard) for automotive seals:

-

Softer seals (40-60 Shore A): Better conformability, lower closing force requirements

-

Harder seals (60-80 Shore A): Better durability, higher closing force needed

-

Dual-durometer designs: Soft bulb for sealing with hard carrier for retention

Buyer Action: Specify application requirements to supplier for durometer recommendation.

Compression Set Resistance

Critical for maintaining sealing force over time. Lower percentage indicates better recovery:

-

EPDM: 15-25% (22h at 125°C)

-

Silicone: 5-15% (22h at 150°C)

-

Neoprene: 20-30% (22h at 100°C)

Buyer Action: Require compression set test data for critical applications.

Environmental and Regulatory Compliance

Modern automotive seals must comply with:

-

REACH, RoHS: Restriction of hazardous substances

-

IMDS: International Material Data System reporting

-

VOC Emissions: Low volatile organic compound materials for interior applications

-

Recyclability: Increasing importance for end-of-life vehicle directives

Buyer Action: Request compliance documentation for target markets.

Cost-Performance Optimization Strategies

Tiered Material Specification

Develop multiple material specifications based on application criticality:

-

Tier 1 (Critical): Premium materials with full testing (safety-related, exterior exposure)

-

Tier 2 (Standard): Balanced performance materials (most interior, protected exterior)

-

Tier 3 (Non-critical): Cost-optimized materials (trim, non-sealing applications)

Total Cost of Ownership Analysis

Consider beyond unit price:

-

Installation costs (ease of assembly)

-

Warranty/liability exposure

-

Replacement frequency and labor

-

Vehicle lifespan compatibility

Regional Climate Considerations

Material performance varies by climate:

-

Hot/Humid: Prioritize ozone and moisture resistance

-

Cold: Emphasize low-temperature flexibility

-

Desert: Maximize UV and heat resistance

-

Coastal: Enhance salt spray/corrosion resistance

Supplier Evaluation and Quality Assurance

Frequently Asked Questions (FAQ) – Automotive Rubber Seal Strips

What is your compound formulation and can it be customized for our application?

What quality certifications do you hold (IATF 16949, ISO 9001)?

Can you provide material test reports from independent laboratories?

What is your production capacity and lead time for samples/production?

Do you have experience with similar applications in the automotive industry?

Can you provide references from other automotive clients?

What is your approach to continuous quality improvement?

How do you handle material traceability throughout production?

Essential Testing and Validation

-

Material Testing: Durometer, tensile strength, elongation, tear resistance

-

Environmental Testing: Heat aging, ozone resistance, fluid immersion

-

Performance Testing: Compression set, sealing force, weather simulation

-

Dimensional Verification: Profile consistency, cross-section accuracy

Future Trends in Automotive Rubber Seals

Lightweighting Initiatives

Development of microcellular rubber and hybrid materials that reduce weight while maintaining performance.

Electrification Compatibility

Materials compatible with high-voltage applications and resistant to coolants used in electric vehicles.

Sustainability Requirements

Increased use of recycled content, bio-based materials, and easier recyclability at end-of-life.

Smart Sealing Integration

Incorporation of sensors and functional elements within seal profiles for condition monitoring.

Conclusion and Final Selection Framework

Selecting the right rubber seal material requires careful analysis of your specific application requirements. Follow this decision process:

-

Identify Primary Exposure Conditions: Temperature extremes, UV exposure, fluid contact, ozone levels

-

Define Performance Requirements: Lifespan expectation, compression force, sealing effectiveness

-

Consider Regulatory Constraints: Compliance requirements for target markets

-

Evaluate Cost Parameters: Budget constraints vs. total cost of ownership

-

Request Supplier Support: Technical consultation and sample testing

-

Validate Through Testing: Application-specific testing before full commitment

For most automotive exterior sealing applications, EPDM provides the optimal balance of performance, durability, and cost-effectiveness. For extreme temperature applications, silicone is worth the premium. For fluid-exposed areas, neoprene or fluoroelastomers provide necessary chemical resistance.

By understanding these material differences and matching them to your specific requirements, you can make informed purchasing decisions that ensure vehicle quality, performance, and customer satisfaction while optimizing costs.

Keywords for SEO Optimization: rubber seal strips, automotive rubber seals, vehicle weatherstripping, EPDM seals, silicone rubber automotive, car door seals, automotive sealing solutions, rubber extrusion automotive, vehicle window seals, automotive gasket materials, neoprene automotive seals, automotive weather seal, car rubber trim, automotive sealant strips, vehicle rubber molding, auto rubber seals, car weather stripping, automotive door seals, rubber seals for cars, automotive rubber products, car window seals, vehicle door seals, automotive rubber trim, car rubber seals, auto weather seals, rubber seals manufacturers, automotive sealing strips, car door weatherstripping, vehicle rubber seals, automotive rubber extrusion.