Creat a one-stop cooperative procument service for rubber seal strips

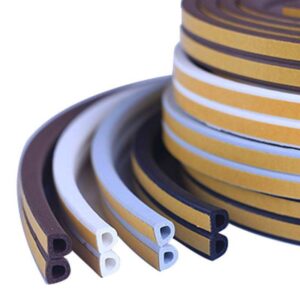

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

High-Performance Rubber Seal Strips for Garage & Door

Garage and door rubber seal strips play a critical role in residential, commercial, and industrial settings by providing weatherproofing, insulation, noise reduction, and security. This comprehensive guide explores the technical specifications, material comparisons, cost-effectiveness, and selection criteria for rubber seal strips in garage and door applications, helping buyers make informed purchasing decisions.

Why Proper Sealing Matters for Garages and Doors

Proper sealing with high-quality rubber strips delivers multiple benefits including energy efficiency, moisture protection, dust prevention, sound insulation, and enhanced security. Inadequate seals can lead to increased energy bills, water damage, pest intrusion, and reduced door lifespan.

Common Garage & Door Seal Problems and Solutions

Air Leakage: Causes drafts and temperature fluctuations

Water Infiltration: Leads to moisture damage and mold growth

Noise Transmission: Reduces acoustic comfort

Energy Loss: Increases heating and cooling costs

Security Vulnerabilities: Compromises safety

Key Material Options for Rubber Seal Strips

EPDM (Ethylene Propylene Diene Monomer) Rubber

Characteristics: Excellent weather resistance, UV stability, temperature tolerance (-40°C to +120°C)

Applications: Garage doors, overhead doors, industrial doors

Advantages: Superior ozone and chemical resistance, long lifespan (10-15 years)

Cost: Mid-range, excellent value for money

Silicone Rubber Seals

Characteristics: Extreme temperature resistance (-60°C to +230°C), high flexibility

Applications: High-temperature environments, food-grade facilities

Advantages: Non-reactive, maintains flexibility in cold conditions

Cost: Premium pricing, specialized applications

Neoprene (Polychloroprene) Rubber

Characteristics: Good weather and oil resistance, moderate temperature range

Applications: Industrial doors, commercial garages

Advantages: Good chemical resistance, flame retardant properties

Cost: Moderate, balanced performance

Natural Rubber Seals

Characteristics: High elasticity and tensile strength

Applications: Residential garage doors, standard applications

Advantages: Excellent compression set, cost-effective

Cost: Most economical option

Thermoplastic Elastomers (TPE/TPV)

Characteristics: Recyclable, consistent quality

Applications: Eco-conscious projects, modern door systems

Advantages: Good weather resistance, lightweight

Cost: Competitive pricing

Material Comparison and Selection Guide

Performance Comparison Table

| Material | Weather Resistance | Temperature Range | Lifespan | Cost | Best For |

|---|---|---|---|---|---|

| EPDM | Excellent | -40°C to +120°C | 10-15 years | $$ | All-around applications |

| Silicone | Excellent | -60°C to +230°C | 15-20 years | $$$ | Extreme temperatures |

| Neoprene | Good | -20°C to +100°C | 8-12 years | $$ | Industrial environments |

| Natural Rubber | Fair | -10°C to +70°C | 5-8 years | $ | Residential applications |

| TPE/TPV | Good | -30°C to +100°C | 7-10 years | $$ | Sustainable projects |

Cost-Effectiveness Analysis

EPDM offers the best balance of performance and price for most garage and door applications. While silicone provides superior temperature resistance, its premium cost is only justified in specialized environments. Natural rubber serves budget-conscious residential projects but may require more frequent replacement in harsh climates.

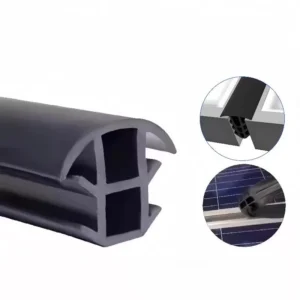

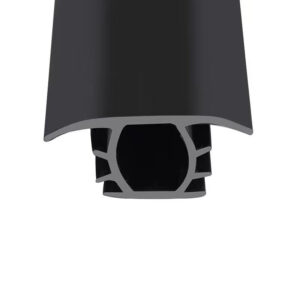

Garage Door Seal Types and Applications

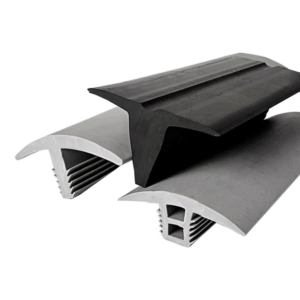

Bottom Seals (Threshold Seals)

Essential for creating a complete barrier between the door and floor. Available in bulb, T-style, and fin designs for different clearance requirements.

Side and Top Seals

Provide sealing along door jambs and headers. Common profiles include U-channel, Q-lon, and compression bulb designs for varying gap sizes.

Astragal Seals

For double doors, providing a seal between two door panels. Critical for minimizing air and water infiltration between adjacent doors.

Installation Best Practices

Proper installation maximizes seal performance and lifespan:

Surface Preparation: Clean and dry surfaces thoroughly

Correct Measurement: Account for temperature-related expansion

Adhesive Selection: Choose appropriate adhesives for the substrate

Compression Optimization: Ensure proper compression without over-stressing

Joint Sealing: Properly seal end joints and corners

Industry Standards and Certifications

When sourcing rubber seal strips, verify compliance with relevant standards:

ASTM Standards: D2000, D1418 (material classification)

ISO Standards: 9001 (quality management)

Fire Ratings: UL94, FMVSS302 (for specific applications)

Environmental: RoHS, REACH compliance

Maintenance and Longevity Optimization

Regular inspection for cracks, hardening, or deformation

Cleaning with mild soap solutions

Lubrication of moving parts with silicone-based products

Seasonal adjustment for temperature variations

Replacement guidelines based on material type and environmental exposure

Customization Options for Specific Requirements

Many applications benefit from customized seal solutions:

Specialized Shapes: Non-standard door profiles

Color Matching: Aesthetic considerations

Compound Modifications: Enhanced properties for specific environments

Integrated Solutions: Combined seal and weatherstrip systems

Regional Considerations for Buyers

North American Market Requirements

Focus on energy efficiency (ENERGY STAR compliance), extreme temperature tolerance, and hurricane-resistant designs for coastal regions.

European Market Requirements

Emphasis on thermal insulation (U-value requirements), environmental standards (REACH), and high-quality aesthetics.

Middle Eastern Market Requirements

Exceptional UV and heat resistance, dust and sand protection, and compatibility with automated door systems.

Asian Market Requirements

Cost-effectiveness, high-volume production capabilities, and resistance to humid, tropical conditions.

Sourcing Considerations for International Buyers

Manufacturer Capabilities: Production capacity and quality control

Logistics: Lead times and shipping costs

Technical Support: Availability of engineering assistance

Sample Programs: Testing before bulk orders

Payment Terms: Flexible options for international transactions

Emerging Trends in Garage and Door Sealing

Smart Seal Technology: Integrated sensors for monitoring seal integrity

Sustainable Materials: Bio-based and recycled rubber compounds

Enhanced Fire Resistance: Improved materials for safety-critical applications

Aerogel Integration: Next-generation insulation in seal designs

Frequently Asked Questions

What is the best rubber seal material for extreme cold climates?

Silicone rubber maintains flexibility at extremely low temperatures, while EPDM offers excellent cold weather performance at a lower cost point.

How often should garage door seals be replaced?

Depending on material quality and environmental conditions, typical replacement intervals range from 5 years for natural rubber to 15+ years for premium EPDM or silicone.

Can I install rubber seal strips myself?

Yes, most residential applications are suitable for DIY installation with proper surface preparation and following manufacturer guidelines.

Are there eco-friendly rubber seal options?

TPE/TPV materials offer recyclability, while some manufacturers now offer EPDM with recycled content and reduced environmental impact.

Conclusion: Making the Optimal Selection

Selecting the right rubber seal strips for garage and door applications requires balancing performance requirements, environmental conditions, budget constraints, and longevity expectations. For most applications, EPDM rubber provides the optimal combination of weather resistance, temperature tolerance, lifespan, and cost-effectiveness. Specialized environments may justify premium materials like silicone, while budget-conscious residential projects can utilize natural rubber with appropriate maintenance schedules.

When sourcing rubber seal strips, prioritize suppliers with transparent material specifications, quality certifications, technical support capabilities, and experience in your specific market segment. Proper selection and installation of garage and door seals represent a small investment with significant returns in energy savings, property protection, and operational reliability.

This guide provides comprehensive information for buyers seeking effective sealing solutions for garage and door applications worldwide. For specific technical requirements or custom solutions, consult with experienced manufacturers who can provide tailored recommendations based on your unique application needs.