Creat a one-stop cooperative procument service for rubber seal strips

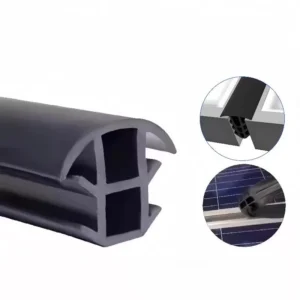

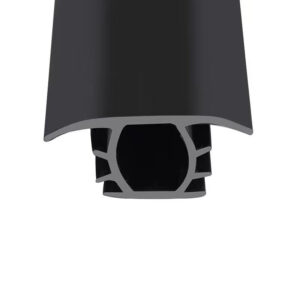

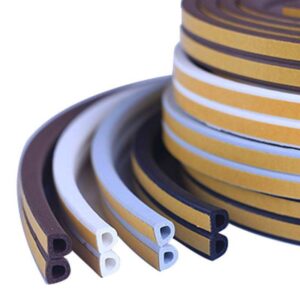

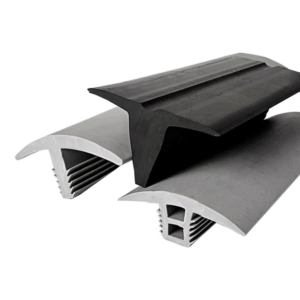

Main products:EPDM sealing strips, silicone rubber sealing strps, NBR rubber sealing strips, FKM rubber sealing strips,neoprene sealing strips, PVC sealing strips, silicone sheet, rubber sheets, EVA foam sheets and rubber gaskets, etc.

High-Performance Rubber Seal Strips for Industrial Equipment

Understanding Industrial Rubber Seal Strips: Core Functions & Applications

Rubber seal strips serve as critical components in industrial equipment, creating barriers against environmental contaminants while ensuring operational efficiency. These sealing solutions prevent leaks, reduce noise, minimize vibration, and protect sensitive components from dust, moisture, chemicals, and temperature extremes.

Primary Applications in Industrial Equipment

Machinery Enclosures: Sealing access panels, doors, and inspection windows on CNC machines, presses, and assembly equipment

HVAC Systems: Sealing ductwork, air handlers, and environmental control units

Material Handling Equipment: Sealing conveyor systems, hoppers, and storage containers

Processing Equipment: Creating seals for mixers, reactors, and separation equipment

Hydraulic & Pneumatic Systems: Sealing cylinders, valves, and fluid power components

Electrical Enclosures: Protecting control panels, junction boxes, and electrical cabinets

Material Comparison: Selecting the Optimal Rubber Compound

Choosing the correct rubber material is essential for performance, longevity, and cost-effectiveness. Below we analyze the most common industrial rubber seal strip materials.

Nitrile Rubber (NBR) – The All-Rounder

Properties: Excellent resistance to oils, fuels, and petroleum-based fluids

Temperature Range: -40°C to 120°C (-40°F to 248°F)

Best For: Hydraulic systems, automotive applications, fuel handling equipment

Cost-Effectiveness: Moderate price with excellent balance of properties

Limitations: Poor resistance to ozone, sunlight, and weathering

Ethylene Propylene Diene Monomer (EPDM) – Weather Warrior

Properties: Superior resistance to ozone, weathering, and water

Temperature Range: -50°C to 150°C (-58°F to 302°F)

Best For: Outdoor equipment, HVAC systems, sealing against steam

Cost-Effectiveness: Excellent long-term value for outdoor applications

Limitations: Poor resistance to petroleum-based oils and fuels

Silicone Rubber – Extreme Temperature Performer

Properties: Exceptional temperature resistance with good flexibility

Temperature Range: -60°C to 230°C (-76°F to 446°F)

Best For: High-temperature equipment, food processing, medical devices

Cost-Effectiveness: Higher initial cost justified in extreme environments

Limitations: Lower tear strength and higher cost compared to other elastomers

Neoprene (Chloroprene) – The Durable Workhorse

Properties: Good all-around resistance to weather, oils, and moderate chemicals

Temperature Range: -40°C to 100°C (-40°F to 212°F)

Best For: General industrial applications, moderate chemical exposure

Cost-Effectiveness: Excellent value for general-purpose sealing

Limitations: Not suitable for extreme chemical or temperature conditions

Fluoroelastomer (FKM/Viton) – Chemical Resistant Specialist

Properties: Exceptional resistance to chemicals, oils, and high temperatures

Temperature Range: -20°C to 200°C (-4°F to 392°F)

Best For: Aggressive chemical environments, aerospace, automotive

Cost-Effectiveness: Premium price for demanding applications only

Limitations: High cost and less flexibility at low temperatures

Cost-Benefit Analysis: Making the Optimal Material Selection

Initial Cost vs. Lifetime Value

When evaluating rubber seal strips, consider total cost of ownership rather than just purchase price. EPDM seals may cost 15-20% more than basic NBR initially but can last 3-5 times longer in outdoor applications, reducing replacement costs and equipment downtime.

Performance Requirements Matrix

| Application Environment | Recommended Material | Cost Category | Expected Service Life |

|---|---|---|---|

| General indoor machinery | Neoprene | Low-Medium | 5-7 years |

| Hydraulic systems | Nitrile (NBR) | Medium | 3-5 years |

| Outdoor equipment | EPDM | Medium | 8-12 years |

| High-temperature (>150°C) | Silicone | High | 4-6 years |

| Chemical exposure | FKM/Viton | Premium | 5-8 years |

| Food processing | Platinum-cured Silicone | Premium | 3-5 years |

Decision Factors for Material Selection

Chemical Exposure: Identify all fluids and chemicals the seal will encounter

Temperature Extremes: Consider both operating and ambient temperatures

Pressure Requirements: Determine if static or dynamic pressure sealing is needed

Environmental Factors: Account for UV exposure, ozone, and weathering

Regulatory Compliance: Consider FDA, NSF, UL, or industry-specific requirements

Movement Requirements: Evaluate compression set and flexibility needs

Customized Solutions for Specific Industrial Equipment Needs

CNC Machines and Precision Equipment

Challenge: Preventing coolant ingress while maintaining precise tolerances

Solution: Custom-profile EPDM seals with high compression set resistance

Key Features: Low outgassing, minimal shrinkage, contamination resistance

Recommended Profile: Dense cellular structure with closed-cell design

Food Processing and Pharmaceutical Equipment

Challenge: Meeting sanitary standards while withstanding cleaning chemicals

Solution: Platinum-cured silicone seals with smooth, non-porous surfaces

Key Features: FDA compliance, steam resistance, non-toxic formulation

Recommended Profile: Solid extruded profiles with rounded edges

Outdoor and Construction Equipment

Challenge: Withstanding UV exposure, temperature swings, and weathering

Solution: Carbon-black loaded EPDM with UV stabilizers

Key Features: Ozone resistance, weather durability, temperature flexibility

Recommended Profile: Hollow bulb designs for enhanced compression recovery

High-Temperature Industrial Ovens and Furnaces

Challenge: Maintaining seal integrity at extreme temperatures

Solution: High-temperature silicone with ceramic fillers

Key Features: Minimal compression set at 200°C+, low thermal conductivity

Recommended Profile: Solid rectangular or custom profiles with thermal barrier design

Installation Best Practices and Maintenance Guidelines

Proper Installation Techniques

Surface Preparation: Clean and degrease mating surfaces before installation

Adhesive Selection: Choose compatible adhesives for the substrate and rubber compound

Joint Design: Implement proper corner treatments and mitre cuts

Compression Optimization: Achieve 15-25% compression for optimal sealing

Avoidance of Stretching: Install without tension to prevent premature failure

Maintenance and Inspection Protocols

Visual Inspection: Check for cracks, hardening, or permanent deformation quarterly

Compression Testing: Verify seal maintains adequate contact pressure annually

Chemical Compatibility Review: Reassess when process chemicals change

Preventive Replacement: Schedule replacement before end of expected service life

Global Standards and Compliance Considerations

International Quality Standards

ISO 9001: Quality management systems for manufacturing

ISO/TS 16949: Automotive industry-specific quality standards

FDA CFR 21: Food and drug contact compliance (USA)

NSF/ANSI 51: Food equipment materials certification

UL 94: Flammability safety standard

REACH & RoHS: European chemical restrictions

Industry-Specific Certifications

Aerospace: AMS (Aerospace Material Specifications)

Automotive: Original Equipment Manufacturer (OEM) approvals

Medical: USP Class VI, ISO 10993 biocompatibility

Marine: Saltwater and weather resistance certifications

Regional Considerations for International Buyers

Temperature and Climate Adaptations

North America/Europe: Focus on wide temperature range materials (-40°C to 150°C)

Middle East: Prioritize UV and extreme heat resistance materials

Tropical Regions: Emphasize moisture and mold resistance compounds

Arctic Conditions: Require specialized low-temperature flexibility formulations

Supply Chain and Logistics Factors

Local Manufacturing vs. Import: Balance cost against lead time requirements

Customs and Duties: Consider trade agreements between manufacturing and destination countries

Inventory Strategy: Maintain regional stock for critical seal profiles

Technical Support: Ensure local language technical documentation and support

Future Trends in Industrial Rubber Sealing Technology

Advanced Material Developments

Self-Healing Elastomers: Materials that repair minor damage autonomously

Smart Seals with Embedded Sensors: Monitoring pressure, temperature, and wear

Sustainable Compounds: Bio-based rubbers with reduced environmental impact

Hybrid Materials: Combining rubber with thermoplastics for enhanced properties

Manufacturing Innovations

3D Printing of Custom Seals: Rapid prototyping and small batch production

Laser Profile Measurement: Enhanced quality control during extrusion

Automated Adhesive Application: Improved consistency in seal installation

Frequently Asked Questions (FAQ)

How do I determine the right seal profile for my application?

Consider the gap size, compression requirements, and sealing surface irregularities. For gaps under 3mm, solid profiles work well; for larger gaps, hollow bulb designs provide better compression recovery. Consult our engineering team for custom profile recommendations.

What’s the lead time for custom rubber seal strips?

Standard profiles: 2-4 weeks. Custom profiles: 4-8 weeks depending on tooling requirements. Expedited services available for urgent requirements.

How can I test rubber seal compatibility with my application?

Request material samples for immersion testing in your operating environment. We provide test kits for common industrial chemicals and temperature conditions.

What’s the minimum order quantity for custom seals?

MOQ varies by profile complexity: $500-$2000 minimum order value. Stock profiles available in smaller quantities.

Conclusion: Making the Optimal Selection for Your Equipment

Selecting the appropriate rubber seal strips requires careful analysis of operational conditions, material properties, and total cost considerations. By matching the rubber compound to your specific environmental challenges and performance requirements, you can maximize equipment reliability, minimize downtime, and optimize long-term operational costs.

For personalized recommendations based on your specific industrial equipment needs, contact our technical support team with details of your application, operating conditions, and performance requirements. We provide free sample kits, material compatibility testing, and engineering support to ensure optimal sealing solutions for your equipment.