Sponge Rubber vs. Solid Rubber: Comprehensive Guide for Industrial Buyers

Understanding the Fundamental Differences

Composition and Manufacturing Process

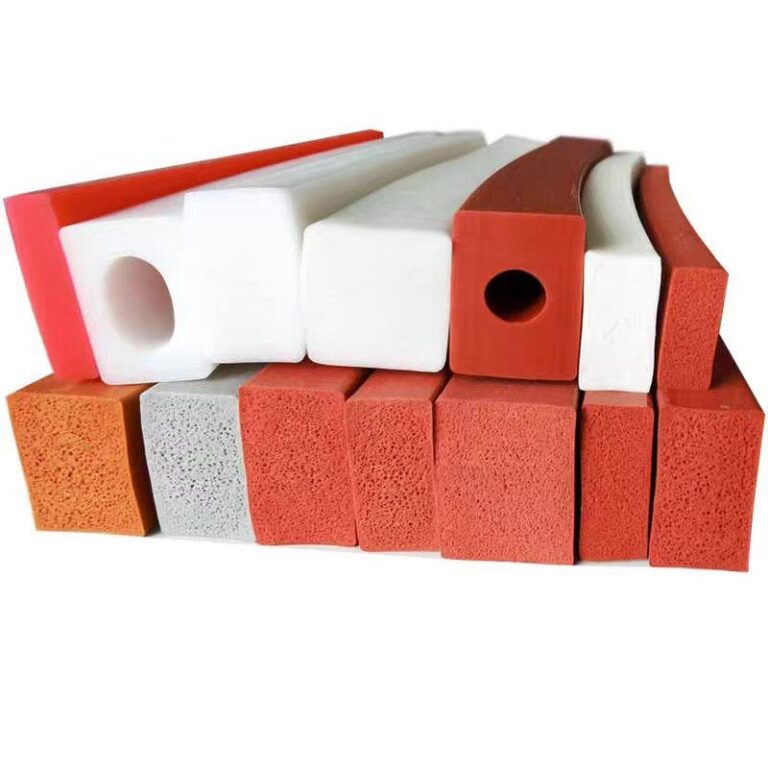

Sponge rubber and solid rubber represent two distinct categories of elastomeric materials with different cellular structures. Sponge rubber, also known as foam rubber, contains a network of interconnected or closed cells created through a chemical or physical blowing process. This structure incorporates tiny air pockets throughout the material, resulting in reduced density and increased compressibility. Common sponge rubber variants include sponge rubber strips, rubber sponge strips, and sponge rubber weather stripping designed for specific applications.

Solid rubber, conversely, features a continuous, non-porous structure without intentional air inclusions. Materials like solid rubber strip, solid rubber weather stripping, and solid silicone rubber strip maintain consistent density throughout their cross-section. The manufacturing process for solid rubber involves compounding, mixing, and vulcanization without incorporating blowing agents that create cellular structures.

Physical Properties Comparison

The cellular structure of sponge rubber strips provides distinct physical characteristics. These materials typically offer 30-70% compressibility, lower density (ranging from 0.3 to 0.9 g/cm³), and superior flexibility. The air pockets within sponge rubber weather stripping contribute to excellent thermal insulation properties and vibration dampening capabilities.

Solid rubber seal strips exhibit higher density (0.9-1.5 g/cm³), limited compressibility (typically 10-25%), and greater structural integrity. Self adhesive solid neoprene rubber strip combines the durability of solid rubber with convenient installation properties. Solid silicone rubber strip maintains consistent performance across extreme temperature ranges while providing reliable sealing capabilities.

Performance Characteristics and Application Suitability

Compression and Recovery Behavior

Sponge rubber strips demonstrate excellent compression deflection characteristics, making them ideal for applications requiring conformability to irregular surfaces. When compressed, sponge rubber weather stripping distributes pressure evenly across the sealing surface, creating effective barriers against environmental elements. The recovery rate after compression varies between open-cell (slower recovery) and closed-cell (faster recovery) sponge rubber formulations.

Solid rubber seal strips provide more resistance to compression, maintaining their shape under constant pressure. Solid rubber weather stripping offers minimal compression set, ensuring long-term performance in applications where consistent dimensions are critical. The recovery behavior of solid rubber strip depends on the specific polymer formulation and cross-link density.

Environmental Resistance and Durability

Solid rubber typically offers superior resistance to weathering, UV exposure, and chemical degradation compared to sponge rubber. Self adhesive solid neoprene rubber strip provides excellent resistance to oils, solvents, and atmospheric conditions, making it suitable for demanding industrial environments. Solid silicone rubber strip maintains exceptional performance in extreme temperatures ranging from -60°C to 230°C.

Sponge rubber strips may exhibit reduced resistance to certain chemicals and environmental factors due to their increased surface area and porous structure. However, specialized formulations of sponge rubber weather stripping can include additives and coatings to enhance environmental resistance for specific applications.

Cost Analysis and Value Considerations

Material and Production Economics

Sponge rubber strips generally offer cost advantages in material utilization due to their lower density. The expanded structure of sponge rubber weather stripping provides more volume per unit weight, potentially reducing material costs for applications requiring bulk sealing solutions. The manufacturing process for sponge rubber incorporates blowing agents that increase yield from raw materials.

Solid rubber seal strips involve higher material costs per unit volume but may provide longer service life in demanding applications. The production of solid rubber strip requires more raw material per unit volume but involves fewer processing steps than specialized sponge rubber formulations. Self adhesive solid neoprene rubber strip combines material costs with adhesive application in a single manufacturing process.

Total Cost of Ownership Assessment

When evaluating sponge rubber vs. solid rubber options, consider installation efficiency, maintenance requirements, and replacement frequency. Sponge rubber weather stripping often provides easier installation due to its compressibility and adaptability to uneven surfaces, potentially reducing labor costs. However, solid rubber weather stripping may offer extended service intervals, reducing long-term maintenance expenses.

For applications requiring frequent access or disassembly, sponge rubber strips may provide advantages due to their resilience to repeated compression cycles. In permanent installations subjected to continuous pressure, solid rubber seal strips typically maintain their performance characteristics longer, potentially offering better value over the product lifecycle.

Application-Specific Recommendations

Industrial Sealing Solutions

For thermal insulation and acoustic damping applications, sponge rubber strips provide superior performance due to their air-entrapped structure. Sponge rubber weather stripping effectively minimizes heat transfer and noise transmission in HVAC systems, industrial equipment, and architectural applications. The compressibility of sponge rubber strips ensures effective sealing despite surface irregularities in manufacturing equipment and machinery enclosures.

In applications requiring fluid containment or pressure sealing, solid rubber seal strips offer reliable performance. Solid rubber weather stripping creates effective barriers against liquids, gases, and contaminants in processing equipment, pipelines, and hydraulic systems. Solid silicone rubber strip provides exceptional sealing performance in food processing, pharmaceutical, and medical applications where hygiene and temperature resistance are paramount.

Automotive and Transportation Applications

Sponge rubber strips find extensive use in automotive weather sealing, vibration isolation, and cushioning applications. The compressibility and recovery characteristics of sponge rubber weather stripping make it ideal for door seals, window channels, and trunk seals in vehicles. The lightweight nature of sponge rubber strips contributes to weight reduction efforts in transportation equipment.

Solid rubber components serve in engine mounts, suspension bushings, and heavy-duty sealing applications where structural integrity and durability are critical. Self adhesive solid neoprene rubber strip provides convenient solutions for aftermarket automotive sealing and repair applications requiring chemical resistance and weather durability.

Selection Guidelines for International Buyers

Climate and Environmental Considerations

Buyers in tropical regions should prioritize materials with excellent moisture resistance and UV stability. Closed-cell sponge rubber strips or solid silicone rubber strip offer optimal performance in humid, high-temperature environments. For Arctic or cold climate applications, materials must maintain flexibility at low temperatures, making certain sponge rubber formulations or specialized solid rubber compounds appropriate.

Industrial buyers in coastal regions should consider materials with enhanced saltwater and corrosion resistance. Solid rubber seal strips with appropriate polymer formulations or specially coated sponge rubber weather stripping can provide durable performance in marine environments. Self adhesive solid neoprene rubber strip offers reliable performance in these challenging conditions when properly specified.

Regulatory Compliance and Industry Standards

International buyers must consider regional regulations and industry-specific standards when selecting sponge rubber or solid rubber products. Food-grade applications require compliance with FDA, EU, or other regional food contact regulations, making solid silicone rubber strip a frequent choice. Medical and pharmaceutical applications demand materials meeting USP Class VI, ISO 10993, or similar biocompatibility standards.

Industrial applications may require compliance with specific fire safety standards (UL, ASTM, BS), making flame-retardant formulations of either sponge rubber strips or solid rubber weather stripping necessary. Automotive applications typically require compliance with industry standards like ASTM D2000, SAE J200, or specific OEM specifications that both sponge rubber and solid rubber products can meet with appropriate formulation.

Sourcing and Quality Assurance

Supplier Evaluation Criteria

When sourcing sponge rubber strips or solid rubber seal strips, evaluate manufacturer capabilities, quality control processes, and testing protocols. Reputable suppliers should provide material certifications, test reports, and compliance documentation for both sponge rubber weather stripping and solid rubber weather stripping products. Manufacturing consistency is particularly important for self adhesive solid neoprene rubber strip to ensure reliable adhesive performance.

Consider suppliers offering comprehensive technical support, customization capabilities, and material testing services. The ability to provide application-specific recommendations for both sponge rubber and solid rubber solutions indicates deeper technical expertise. International buyers should verify supply chain reliability, lead time consistency, and logistical capabilities when sourcing these materials globally.

Quality Verification Practices

Implement incoming quality checks for critical parameters including durometer hardness, density, compression set, and dimensional tolerances for both sponge rubber strips and solid rubber seal strips. For sponge rubber weather stripping, verify cell structure consistency and compression recovery characteristics. For solid rubber weather stripping, evaluate tensile strength, elongation, and tear resistance appropriate to the application.

Conduct application-specific testing under simulated service conditions to validate performance of both sponge rubber and solid rubber options. Accelerated aging tests can help predict long-term performance of solid silicone rubber strip in high-temperature applications. Environmental exposure testing validates the suitability of self adhesive solid neoprene rubber strip for challenging service conditions.

Conclusion and Decision Framework

Summary of Key Differentiators

Sponge rubber strips excel in applications requiring compressibility, conformability, thermal insulation, and vibration damping at potentially lower material cost. Solid rubber seal strips provide superior structural integrity, environmental resistance, and durability in demanding applications with continuous pressure or exposure to challenging conditions.

Final Selection Recommendations

Choose sponge rubber weather stripping for:

-

Thermal and acoustic insulation applications

-

Sealing irregular or uneven surfaces

-

Applications requiring significant compression

-

Weight-sensitive applications

-

Cost-sensitive projects with less demanding environmental conditions

Select solid rubber weather stripping for:

-

Fluid and pressure sealing applications

-

Continuous load-bearing applications

-

Environments with chemical exposure

-

Applications requiring minimal compression set

-

High-temperature or extreme environment applications

Consider self adhesive solid neoprene rubber strip for convenient installation in maintenance and repair applications requiring chemical resistance. Utilize solid silicone rubber strip for extreme temperature applications or where regulatory compliance is critical.

International buyers should evaluate application requirements, environmental conditions, regulatory constraints, and total cost considerations when selecting between sponge rubber and solid rubber solutions. Consulting with technical specialists and requesting material samples for application testing can ensure optimal material selection for specific project requirements.